Forum › Forums › Tractor Troubleshooting › Engine knocking

- This topic has 123 replies, 11 voices, and was last updated 12 years, 2 months ago by

Bob Rooks.

-

AuthorPosts

-

-

November 21, 2012 at 11:57 pm #30691

I have a JM 284, 2007 model I bought slightly used in late summer of 08. This tractor has now been sitting for a couple of years due to a problem that cropped up, and I got disgusted with trying to fix it, so I parked it under an overhang and left it. That was about 2 1/2 years ago. Well, I am going thru all my projects, getting things done that have been waiting, and now it's timne to get the Jinma fixed and running again.

The problem started when I was running it moving snow. Was doing fine when it started kinda hammering and putting out white smoke etc. Tshot, replaced a couple of injectors etc but never did really seem to fix it. Still had the knocking and sounded like it was coming from down low. That's when I got disgusted and parked it. Okay, so today I dragged it into my garage, and checked the oil level. Was way up on the dipstick. I mean WAY UP! I drained the oil and got 2 gallons out of it. No sign of water in it. I did try at one point to see if it would turn over but all it would do is click once. Battery is full charged.

So now, I will see if I can turn the engne by hand/wrench/whatever and see if it is locked up. I was running when I parked it so it shouldn't be. But it only has about 160 hours on it so it shouldn't be dead either. We'll see. Wondering if fuel ran into the engine as it sat, causing the level to go so high, or could it be hydraulic oil has leaked into it? Sorry, I'm starting off cold on this one again after being away from it for so long.

-

November 22, 2012 at 10:23 am #35299

Check your hydraulic oil behind the seat, sounds like you might have bloown a pump seal and it has filled up your enige crankcase with hydraulic fluid. Sometimes a hydraulic dead head will cause the pump seal to blow out

Happy Thanksgiving

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

November 22, 2012 at 10:34 pm #35301

Thanks Tommy,I will check that. The hydraulics as best as i can recall, were working fine right up to when I parked it, but anything is possible.

-

November 22, 2012 at 10:52 pm #35302

Does your exhaust pipe stick up in the air? If so it could have water in one or more cylinders causing hydra lock.

-

November 22, 2012 at 11:27 pm #35303

I concur with Carl.

Try removing the injectors or glow plugs and see if it will crank over.

Aside from the hydraulic pump deadheading, you could also have a dribbling injector, which, over time, will partially fill a cylinder with fuel. Other possibilities are a cracked cylinder liner/head, or a bad head gasket. I assume you have the proper type and mix of anti-freeze/coolant meant for diesel engines?

Account deleted.

-

November 23, 2012 at 9:36 am #35304

The tractor was under cover so I doubt water got in, but I will check to be sure. Stranger things have happened. The dribbling injector has always been a possibility, even thought I had replaced one or two of those I suspected (it's been a while so I don't remember for sure if it was one or two). And yes, it had good antifreeze in it all along. I'll start getting into it today and see what shows up, and then post the results.

-

November 23, 2012 at 1:20 pm #35305

Okay, update #1. Good news is, the engine is not locked up. I remembered there being an access cover on the left side that would give me access to the flywheel and ring gear. tried moving it with the help of a screwdriver and it moved easily. So I have an electrical issue to begin with. Clean all battery posts and other similar contacts and see what that does for me. However……….. checked the hydraulic level and it didn't register on the dipstick. So I stuck a piece of hose down into it and it shows about an inch and a quarter of fluid on it. Not good.

Second however;, I checked the radiator and it showed low. So I drained it at the lower petcock, and got maybe a quart out of it. Second not good. I don't see any signs yet of any external leakage, so I suppose next I pull the valve cover and look for signs of something unhappy in there. And keep going untill I can identify where the antifreeze went. Of course, I'm thinking how much this is gonna cost to get the tractor running, and how much a shortblock might cost, etc, etc, etc.

-

November 23, 2012 at 2:41 pm #35306

Being low on coolant could just be a matter of not having a coolant recovery system installed, or a bad radiator cap, allowing the coolant to burp out of the overflow tube.

Keeping fingers crossed for you.Account deleted.

-

November 23, 2012 at 3:59 pm #35307

Yes, fingers crossed. I cleaned up all the battery connections, but still nothing when I hit the switch. I did get the starter to run by shorting across, but haven't tried to get the solenoid to engage by shorting across it. Doesn't seem like the juice is getting to the solenoid to kick it, just yet. Still pokin around. Also took the valve cover off, no signs of any unhappiness in there yet.

-

November 23, 2012 at 4:29 pm #35310

Check the clutch safety switch, I think it's under the deck plate. These have been known to be problematic or just out of adjustment. Remove the wires and connect them together or just jumper them. Be sure the transmission is in neutral.

Account deleted.

-

November 23, 2012 at 4:50 pm #35312

I agree with Bob – clutch safety switch is a known weak spot on these. My 304 uses tiny little wire to/from the safety switch, actually. I replaced it with heavier wire to make me feel better. (grin)

Chinese tractors have issues with marginal cooling systems. Just a bit of chaff or dirt will decrease cooling enough to make them overheat just enough to boil fluid out the overflow tube – pretty soon, very low coolant and big overheat. A 1-lliter pop bottle and some clamps will make a satisfactory recovery bottle. One of the harder bottles like bicyclists sometimes use would be even better.

These tractors also lose hydraulic fluid from the sump breather when they go up steep grades. Check for signs of oily tracks down the back of the lift box. You can add a piece of hose to re-route the breather up along one of the ROPS arms to stop the drooling issue.

I'd suggest draining a bit of the engine oil. If you're on level ground and very careful when you pull the sump drain plug, if there is water (coolant) in the sump it will come out first. I suggest draining out a gallon or so fluid into a clear plastic jug so you can see what you have. If you let it sit a day or two, oil/water will separate and sometimes, even engine oil and hydraulic fluid will tend to separate enough to see a difference. Might be informative. Oh – smell it, too. Diesel fuel has a distinctive smell, as does some hydraulic fluid.

As Tommy said, a blown seal on the hydraulic pump can let hydraulic fluid get into the engine sump.

-

November 23, 2012 at 5:17 pm #35313

I had a jumper wire on that interlock. Still not certain that isn't an issue yet. I'll do some electrical checks to make sure I know it's good. The hydraulic tube I had on a long tme ago for just that reason.

I used to be a regular on the old forum and got lots of good tips like that back then. That's why when I decided it was time to get the Jinma going, I knew to come back here for the assistance.

I have already drained the crankcase, got 2 gallons out of it, but no sign of water at all there. Not milky, just dark oily, etc. I'm thinking the hydraulic seal is the more likely culprit, because I still have well over a half tank of fuel in it. Guessing it it was fuel leaking thru it would just keep leaking thru till the tank was empty. We'll see. Hope the fix, when I find it, isn't too spendy.

-

November 23, 2012 at 7:21 pm #35314

Okay, I cleaned up my jumper wire for the cllutch interlock and got it to try to turn over. So I pulled all 3 injectors, and it turns over freely now. Got some vapor out of the holes, but no spray of liquid, so I am somewhat hopeful. The injectors however I'm not so sure of. The front one was sooty, the middle one was even sootier, and the back one was sooty and a bit wet. I kept my grubby fingers off the nozzles and whatnot and just set the injectors aside for now. I have two others I had pulled from the tractor before when I had began having the troubles, nd they are much cleaner. I had stored them with the plastic covers in place so they may be usable for now. Do I attempt to clean the sooty injectors? Best method? If I have to replace them what's the cost?

-

November 23, 2012 at 8:21 pm #35315

Someone else can correct me if I'm wrong but i believe soot is normal.

-

November 23, 2012 at 8:30 pm #35316

I'm sure ready to accept “soot is normal”! On that note I'm gonna put the injectors back in their holes. Hmm….maybe not just yet. There has to be a reason it wouldn't turn over until after I pulled the injectors. But I don't want to pull the head unless I have to. Recommendations?

-

November 23, 2012 at 11:01 pm #35317

Okay, put the injectors back in, after giving them a spray with carb clean and wiping the barrel of them off. Didn't touch the little nozzles. Did notice one injector….when I went to install it, there was no washer on it. I looked around and down in the hole, but no washer. No sign of it having fallen off either. Couldn't get the washer off my extra injector, so I put that extra in, with it's own washer.

Went to put the valve cover back on. %#@^!!! What's the magic trick to getting the de-compression coupling back in place while installing the valve cover??? Kept messing with it, put some heavy grease on it and tried again about 15 times. The last time, I think, maybe, hopefully, I got it on and in place. Didn't hear the dang thing drop off anyway. Oh well, tomorrow gotta get some oil and some coolant and see what's what. Bleed the injector lines etc.

-

November 27, 2012 at 11:18 am #35327

Had other things going on for the past few days, but yesterday i had a bit of time to spend on the tractor issues. Got the coolant topped off and was looking things over, and discovered to my disgust, I had let that tractor sit all that time, with the fuel shut-off, in the ON position. Further, when I pulled the dipstic on the injector pump, fluid (I presume a combination of oil and diesel fuel) ran out. So I drained the oil from it and let is drip for about 30 minutes. Forgot what a PITA it is to add oil to that thing. Had to quit before I finished, so I'll get back to that today. I'll roll the tractor out of the shop to start it, to avoid smoking up the place. Will update once I have anything further to add.

-

November 27, 2012 at 10:22 pm #35328

Won't go into what-all I went thru, but I got it running this afternoon. Lotsa pre-heat, and lotsa keep on trying, but I finaly got it to run and keep running. Bled the lines and so on. Still have the knocking. Not 100% of the time, but 95% anyway. I'm gonna take the valve cover off tomorrow and see what the valves are doing while it runs. Just wondering if I have a bent pushrod, stuck lifter, something along those lines. I know it's hitting on all 3 cylinders cuz when I crack each line, the rpm drops off. But I can't yet pin down what is causing the knocking sound. It seems to be about midway down the side of the block, but I can't even be sure of that.

-

November 28, 2012 at 7:27 pm #35329

I would look at the fuel system, I believe you have solid lifters and why would a push rod bend unless something was not put together correctly from the factory which I think would have showed up much earlier.I know that the adjustments on the lifters has been a issue but as for my 2 tractors were only talking a few thousands one way or the other.nothing that would bend a rod. and if it comes and goes that should not be a solid lifter or rod.earlier you were talking soot maybe uncomplete combustion due to fuel injector,pump issue?and that might be a hard to start cause also.

-

November 29, 2012 at 7:46 am #35337

as I was looking threw the post I did not see anything about oil pressure.if you think a piston rod bearing is knocking? was there anything that would have caused this kind of failure? lack of oil,water in oil.if all you got is a oil light ,place a mech. gauge to get a reading.

-

November 29, 2012 at 10:04 am #35338

Thanks Dave. I pulled the valve cover off again yesterday and all looked to be working as normal. I did NOT see as much oil working up there as I had expected, but it was getting oil. My pressure gauge now seems to be whacked out, had been sitting at 6, turn swithch on it'd go to zero than gradually back up to 6, and then after start, stay at 6. Well, yesterday it's pretty much pegged at 10. So when I go into town today, I'll get a mechanical pressure gauge.

This all started when I was pushing snow down a hill. All had been fine up to that point. I thought it was a rather loud, bad injector, but after replacing 2 of them, there was no improvement. When I crack the lines to each injector, I get a drop off for each cylinder indivdually.

So far, no signs of oil in water, nor water in oil.

It is starting much better now, even with the cooler weather. I hit the glow plugs for about 30 seconds, and it'll crank a bit, and then pick up and start firing. I hit the glow plugs while it's running, and it'll smooth out. No white smoke now. But I don't run it very much while troubleshooting cuz I just hate that knocking sound. Had resolved to drain the oil again and pull the pan today, but I'll put a pressure gauge on it first and see what I see. I don't want to have to tear that engine down, but it's sure looking like that's what it'll come to before this is over. With luck, I'll have some more facts to ponder by the end of this day.

-

November 29, 2012 at 2:29 pm #35345

Okay, direct reading Oil Pressure gauge installed. I put in a tee so I could still use the factory sending unit for the dash gauge. New direct reading gauge reads 50 psi, give or take. Dangit, the tractor starts good and runs decent and if I was deaf, I wouldn't know there was a thing wrong!

-

November 29, 2012 at 6:31 pm #35346

Drained the oil, unbolted the oil pan. Looks to em like th front driveshaft is gonna be in the way, especially if things look ugly with the pan off. Other than taking out the 4 bolts on the front flange, and taking the hose clamps loose from the boot on the dr shaft halves, is there anything I should watch for at this point? Do I just pry the flange away from the front diff to pull the drive shaft? Do I have to take it lose from both ends? I planned to just pull one end to move it over out of the way, but….. There used to be more info like that in the old forum, but I guess I'm not smart enough to figure out how to get to those old posts, or at least the info.

-

November 29, 2012 at 8:08 pm #35347

Maybe there was some trash in the oil that made it to the oil hole in the crank that feeds the bearing .I sure hope not. that would be a crank and and bearings.have you tryed one of those mechanics stethoscope maybe you can narrow it down some.harbor freight has them cheap.

-

November 29, 2012 at 9:05 pm #35348

The knock seems to be coming from the right hand side, about halfway up the block, and towards the front. That's as much as I can narrow it down. Occasionaly it'll skip a knock, but not with any regularity. Every now and then, I can hear a faint squeak. Only time I have ever heard something similar, was in my 83 Ford with 6.9 diesel, and 330,000 miles. Took $2000, a re-ground crank and a new connecting rod to fix that. And that was back in 92!

Still waiting for info on removing the front drive shaft. Any suggestions?

-

November 30, 2012 at 10:02 pm #35351

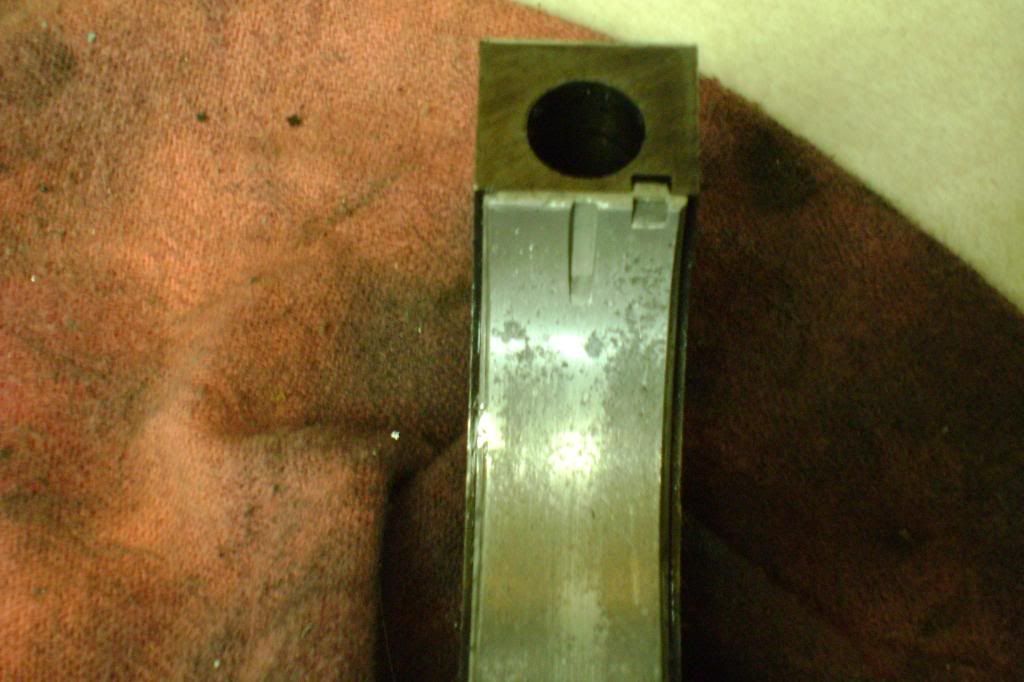

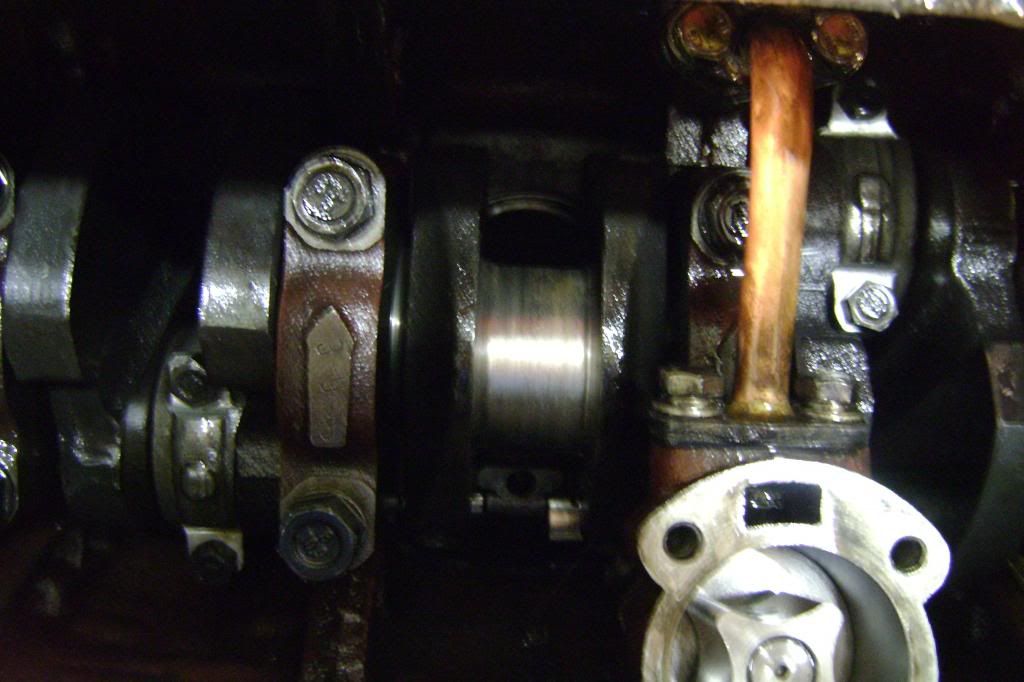

One rod bearing and cap.

-

November 30, 2012 at 10:15 pm #35352

Those bearings look a little rough to me. How does the crank journals look?

-

November 30, 2012 at 10:50 pm #35353

I haven't popped the crank caps yet. Once I saw that rod bearing and cap, I sorta knew I was in for the full teardown, like it or not. It looks to me like the bearing may well have rotated in the cap, just from the roughness of the outside of the bearings and the cap.

-

November 30, 2012 at 11:09 pm #35354

I believe Carl was asking how the crankshaft looks where those bearings contact it, not the mains. If everything else checks out OK, and that journal cleans up, you may get by without a teardown. Being a diesel I'm figuring it's a forged crank

, so it should be good and hard. Is the rod and cap OK where the bearing spun? If you can get your hands on a dial caliper it would sure help, and maybe save a lot of time taking things apart.

, so it should be good and hard. Is the rod and cap OK where the bearing spun? If you can get your hands on a dial caliper it would sure help, and maybe save a lot of time taking things apart. -

November 30, 2012 at 11:53 pm #35355

Thanks Tinbender, and yes I should have realized that's what he was asking. The journal for that one looks rough to me as well. I haven't looked at the rod itself too closely yet, kinda tough for an old man to crawl around under the tractor, lol. I haven't yet determined for sure, what was doing the knocking, but I am hopeful by taking off the other rod caps I can pinpoint it. I can hunt around and see if I can come up with a dial caliper, either from the parts house I use locally, or perhaps from a pawn shop.

With the ground up bearing material floating around throughout the engine, isn't it gonna have to be taken completely apart to flush it out and make sure I have all the residue out? I hate doing this job,and I'd doubly hate to have to do it again later. Seeing the other two rod bearings and such should tell me a lot more, but that's gonna have to wait till tomorrow, and possibly longer. I have a Christmas project for my granddaughters I need to get done, and I'm thinking I'll do that before I dig much deeper into this engine. It's inside the garage. and it ain't going anywhere. Once I have those rod caps off, I'll post pics of those as well.

-

December 1, 2012 at 12:44 am #35356

That bearing has spun. The indexing tab is missing on both halves. The crank will have to be removed and re-ground, regardless. You can mic the crank and compare it to specs to see if you can get away with .010″ on the grind. The rod and cap will also have to be reconditioned. That's a real bummer.

Account deleted.

-

December 1, 2012 at 8:51 am #35357

That's kinda what I thought Bob. And I am also guessing most of the other journals will be comparably damaged, which begs the question, does it make sense to have it re-ground, or best to just get a new crank? How far do ya go before replacement is wiser than re-conditioning?

Probably what annoys me the most about all this is, I should have followed my own gut instinct when the knock first appeared. “They” kept telling me it had to be a bad injector, but I felt like the knock as too loud to be that simple. “They” weren't there to actually hear the knock. What's past is past, and I can't undo what's been done. But knowing I probably could have saved myself a whole lot of money, time and trouble if I had followed my own suspicions just annoys the heck outta me.

Wonder if any of the dealers sell a short-block for a Laidong KM 385 engine. Or, if anybody knows of a good used engine to be had at a decent price.

-

December 1, 2012 at 10:20 am #35358

rdstevens wrote:

“How far do ya go before replacement is wiser than re-conditioning?”

That decision is usually made by cost weighting factors. How much does a new crank cost (incl. shipping) vs. a fully re-ground crank? Are oversize bearings even available? (there might be compatible alternatives – check with Federal-Mogul, etc.) It might be cheaper to just replace the rod.

Account deleted.

-

December 1, 2012 at 12:31 pm #35359

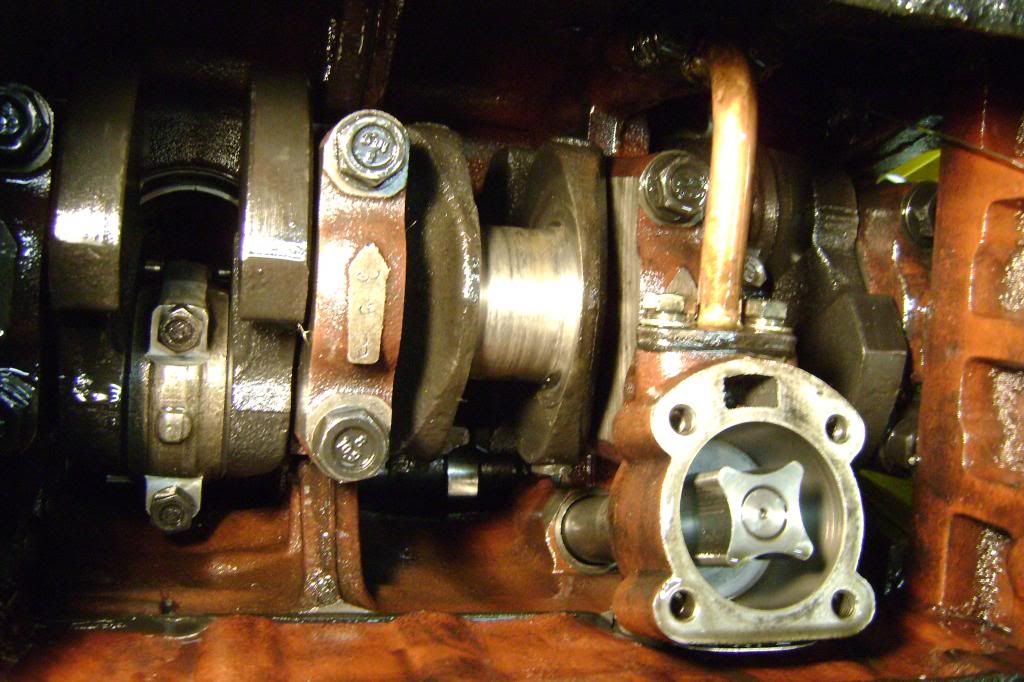

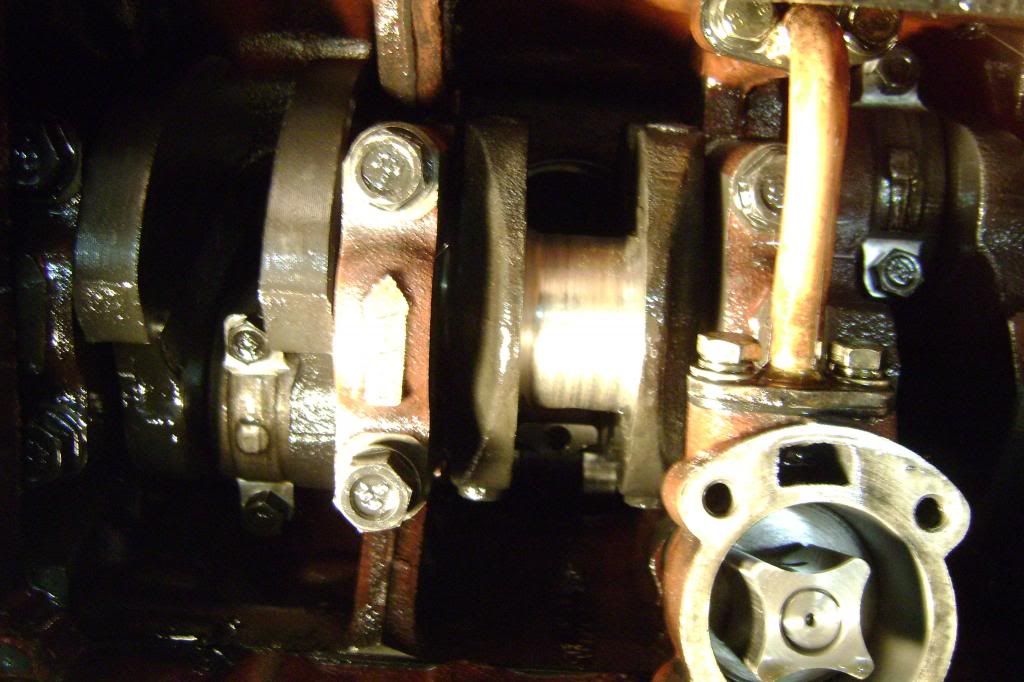

This is the main bearing, #2 from the front. That journal doesn't look too bed. Far better than the journal with the earlier rod bearing.

-

December 1, 2012 at 2:04 pm #35360

Pulled the other two rod caps, and they both look as good or better than the main! Tempted at this point, to clean up the bad journal with emery cloth, and if it mics to within .0010 of spec, install a new rod and bearing, gaskets where needed, torque to specs, fresh oil and filter, and fire it up and see what it does. It may not work out and I may have to tear it back down again for more extensive repairs, but if I can make it run right without knocking and avoid splitting the tractor……..

-

December 3, 2012 at 12:05 am #35369

The looks of those bearing inserts suggests very dirty oil. The center of the inserts are relatively clean where the oil enters but as it thins out toward the edges it's leaving deposits in the aluminum, and in some cases even pitting it. This symptom can be caused by several things:

A poor quality oil filter. Poor quality lube oil. Low oil pressure. High soot content in the oil. Oil is running too cold.

I would at least Plas-T-Gauge all of the remaining journals and mains.

Account deleted.

-

December 3, 2012 at 7:30 am #35370

makes me wonder how long the original chinese junk oil was in the crankcase,but it dont matter now.

-

December 3, 2012 at 9:12 am #35371

Bob I very much appreciate your input, and yes I will plasti-gauge each insert. This tractor had been the dealer's own personal tractor for the first 60 hours, so I have to assume it was properly prepped and broken in before I got it. The filter I use is the recommended NAPA filter. As for cold oil, that could be a possibility, though I tried to always let the engine warm up before putting it to use, used a magnetic heater on the pan to prewarm the oil etc. I now have a block-heater to install in it once I drain the coolant.

What do you guys use for torque settings on the mains and on the rod-caps? This is the KM385 BT series, Laidong engine.

-

December 3, 2012 at 1:30 pm #35373

I do not know if this is a even near perfect way to tell if the engine is at a temp to start working it,but I grab the oil filter and feel how warm it is before I put some rpm to it.

-

December 3, 2012 at 5:38 pm #35376

I’d say if you can comfortably hold the oil filter, the engine is not warmed up enough to put a load on. 140F is too hot to holdand most diesel engines like to be above 170 for optimun power and wear.

-

December 4, 2012 at 3:35 am #35380

Modern engine lubricating oils perform best between 180°F and 200°F, but 170°F is better than nothing.

Account deleted.

-

December 4, 2012 at 10:09 am #35381

It's been a while since I ran this tractor but as I recall, I'd take it pretty easy on it till the temp got up to 80c (assuming some degree of accuracy inherent in the temp gauge), and it'd go up to around 90c during normal working. Now, I am old enough I never got the “c” to “f” conversion, but was told 80C is about normal.

If the tractor requires more warm-up than that before moving it around the place, then I have to conclude, it's just too delicate for me to get much use of around here, and I'll fix it, sell it, and continue using my 640 Ford for my tractor needs. The old Ford requires minimal warm-up before I start moving it, and it gets to about 190f getting to to where I will be wsorking it, and it stays there the whole time I'm using it. Not as handy as the 4X4, ps and live power, but I've made do in the 3 years the diesel tractor has been parked to the side. It has a Du-Al loader, runs my brush-hog mower, my back-fill blade, my box scraper and my LITW backhoe just fine.

Anyway, nuff on that subject. I need more coffee, and some shop time working on my Christmas gift to my granddaughters. Ya'all have a great day!

-

December 4, 2012 at 12:38 pm #35382

You're in the ballpark anyway.

Happy seat time.

80 degrees Celsius is 176 degrees Fahrenheit.

The conversion formula is F = (C x 9/5) + 32.

I just turned 72.

Account deleted.

-

December 4, 2012 at 2:29 pm #35383

I remember on the old site 50c figure was given as a temp to start puttin around. like to get where you are going be fore putting the tractor to workin.I assume that is reasonable.

-

December 4, 2012 at 4:34 pm #35384

Well, if you need that short block, we have them in stock.

Merry Christmas

Ben

Circle G Tractor Sales, Inc.

-

December 4, 2012 at 8:28 pm #35388

Ben, I looked thru your site and found the individual bits and pieces, but I didn't see any reference to a short block. Now, in my world, a short block is the block complete with sleeves, pistons, rings, rods and bearings, crank and bearings, cam and bearings, freezeplugs, oil pan, and so on, all installed. Not a complete engine, but one ready to install the head, lifters and pushrods, timing assembly, oil pump, injector pump, water pump, and so on. Is that what you are referring to?

-

December 13, 2012 at 11:20 pm #35417

After giving the situation a lot of thought, and after micing the rod journal and determining the wear is just too much, I am resigned to splitting the tractor and pulling the crank. I don't know if an oversize rod bearing can be found for it or not, but if not, then of course I'm tapped for a new cranshaft. And main bearings and rod bearings, and a new connecting rod. I just don't see any other way around it. So I have gotten a start on the job, pulled the hood off, pulled the loader off. Drained the coolant. Pulled the upper and lower rad hoses off. (Note, need new rad hoses). Tomorrow, will continue with the dismantle and on with splitting the case.

-

December 14, 2012 at 1:21 am #35418

This is a small part of this project, but don't buy Chinese replacement hoses, take the old ones to a parts store and find something to cut to match. Chinese rubber leaves something to be desired.

-

December 14, 2012 at 6:16 am #35419

Heh, yeah, I'll agree to that. Same for the intake line from the air filter. I will probably re-engineer that set-up to make the hose shorter and find some better hose for it asd well. Once I get it all put back together.

-

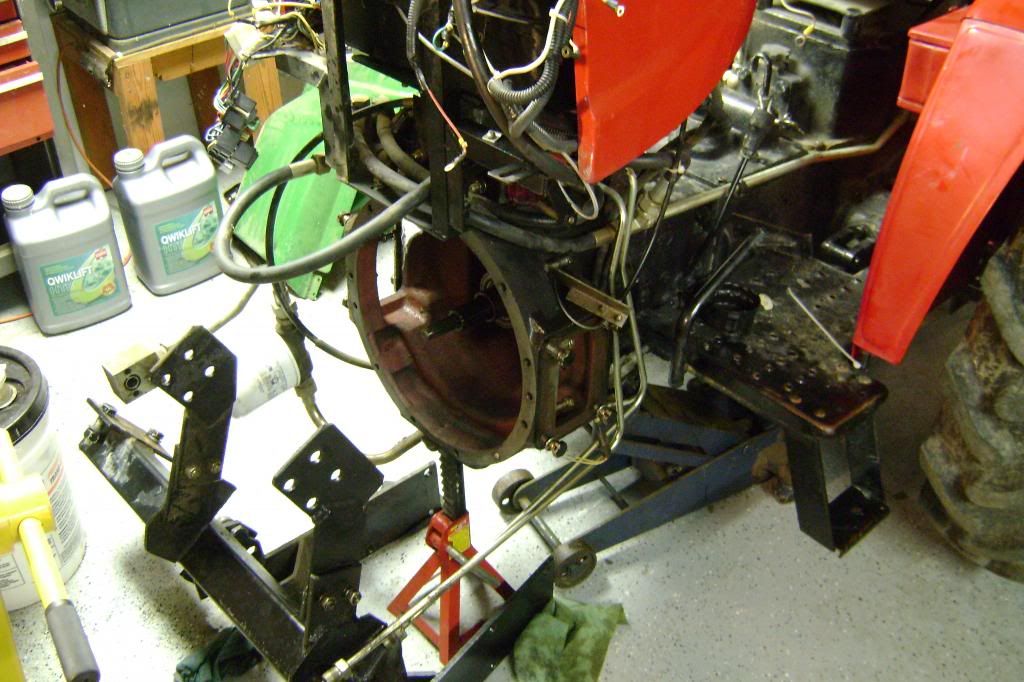

December 14, 2012 at 8:00 pm #35422

Well, I have it split, the clutch, pressure plate and flywheel off, the adapter plate off, and the tools put away for the night. Once I locate an engine stand to mount the engine to while I work it over, I'll get back at it. For now, my big floor jack is holding the transmission up, my porta-crane is holding the engine up, and I have jack stands under both just in case.

I live alone and am out in the country so if anything happened, I'm on my own. Forces me to be a bit more cautious and think things thru carefully before I jump in.

Anybody have ideas where a guy might be able to get oversize rod bearings for these tractors?

-

December 14, 2012 at 11:07 pm #35423

Federal Mogul is probably your best bet. Most NAPA stores with a machine shop handle the brand. Your local (real) auto parts store may also have a lead. Take a good bearing set in as a specimen.

A good parts person should be able to match up a set from the dimensions.

Don't be surprised if they are the same as a '37 Dodge.

Account deleted.

-

December 14, 2012 at 11:43 pm #35427

Thanks Bob! We used to have several good machine shops in town, in conjunction with parts houses, but they've pretty much all gone by the wayside. However, there are a few good ones within 100 miles. If I can make that work out, I'll do that rather than spring for the cost of a new crank. We'll see just how much has to be taken off the one bad journal. I don't think it's too bad, but that'll be up to the machinist.

-

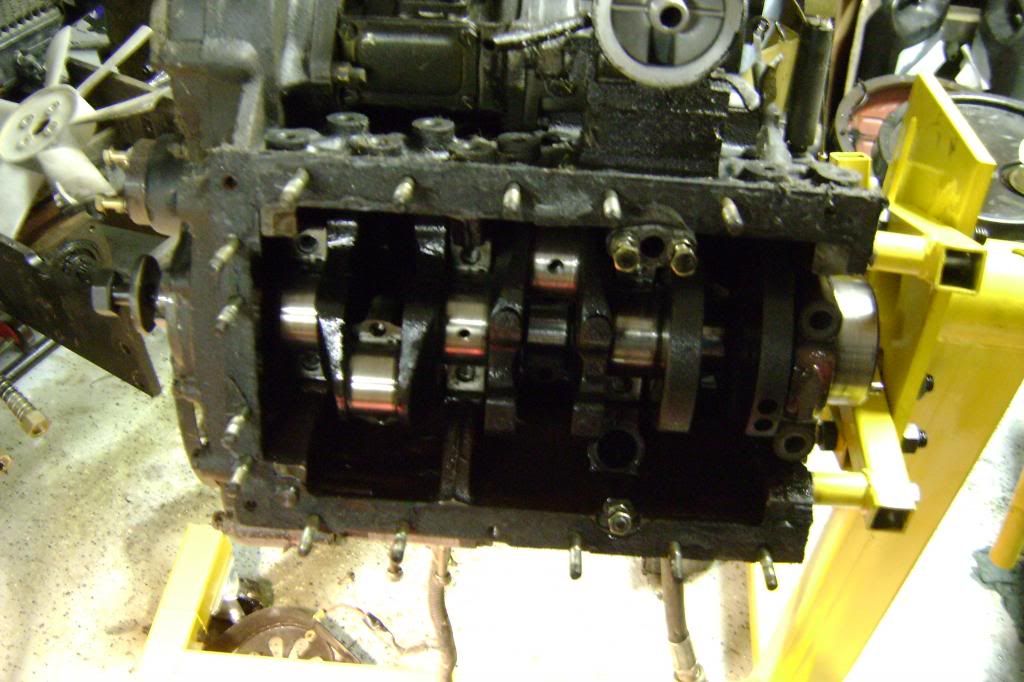

December 16, 2012 at 12:52 pm #35429So I called around to find an engine stand. Rental place wanted $15 a day or $45 a week. Pronto parts place in town had one on sale for $79. Use it once, sell it for $50, still money ahead. Of course, after I put it together i realized I didn't have any metric bolts to bolt the block to the engine stand, so back to town. Pronto had some, almost long enough, and he threw them in cuz I bought the engine stand there. So went back home, did a little modification so the bolts I got would be long enough.

Finished seperating the engine from the front parts, pulled the sump and the crank pully. Then marked all rod caps and bearing caps, and starte unbolting them. Got them all except the rear main cap doesn't

want to come off. It's loose but still stubborn. Time to go look at the parts book and see if there is something I may have missed. I also still have to pull the timing cover, but I want to lok that over real carefully, so I don't have a timing nightmare when I try to reassemble it.

-

December 17, 2012 at 3:07 pm #35433

have you found a reason for the damage yet ?

-

December 17, 2012 at 6:21 pm #35434

All I know so far is, one rod bearing spun. I don't yet know why it would have yet. Will be pulling the head and valve train off tonite. Don't expect to see anything untoward there, but who knows. With that off, I will then pull the crank off and get a better look at that whole thing. Do the measurements and so on. Will post more pics once I have all that done.

-

December 17, 2012 at 8:36 pm #35435

Yes, RD we do have the complete Engine with everything you mentioned should you need it just give us a call. 662-252-5272

Ben

Circle G Tractor Sales, Inc.

-

December 17, 2012 at 10:15 pm #35436

Pulled the head off. Pulled the timing gears and gearcase off. Pulled the crank. Found a plastic breadwrapper twisty tie stick in one of the oil holes of the crank. The back cylinder had a lot more soot,and the cylinder liner looked cruddy inside. Will take and post photos in the morning. Tonite I'm gonna chat with my son who is in Afghanistan.

Amazing. Back when I was over in the land of jungles and Lil nasty folks, the only time I had a chance to talk with anybody stateside, was when we went back to re-supply and once a month we might get to call on a MARS line. courtesy of Barry Goldwater.

-

December 18, 2012 at 7:01 pm #35437

Crank pulled out.

mic'd the “bad” rod journal. Not terrible

Other rod journal.

mic'd the mains, all read the same.

front piston. note the skirt scuffing.

middle piston. Again, skirt scuffing. This is the one with the spun rod bearing.

Back cylinder. Again skirt scuffing AND rust staining noted on top!

next 2 photos show the erosion inside the back sleeve.

Top deck. I see no signs of a head gasket leak. But after sitting for almost 3 years, it was way low on coolant.

Okay, so after viewing the damage, I'm asking for expert advice, from someone who isn't gonna make money on the choice. Is the piston scuffing significant enough to justify replacing the pistons? Sleeves? I know the back one has to be replaced.

As for the moisture damage, I looked and don't see any signs of head gasket leakage, but I will certainly have the head checked for flatness when I take the crank and rod in for machine work. It is possible some got in ther exhaust pipe during the time it was sitting (knew I shoulda bought and installed a rain cap when I first brought it home).

Sure wish I had a mechanic-type friend living close by, lol.

-

December 19, 2012 at 12:02 pm #35439

Doing great Roger.

If you can, mic the pistons and liners see what the difference is. Also, check the useable liners for concentricity and taper, they may clean up nicely with a hone or berry brush. Pistons can be cleaned up and knurled at the machine shop if they pass the fit test, however new pistons may be just as inexpensive.

Account deleted.

-

December 19, 2012 at 7:52 pm #35441

Much as it pains me bob, I think I'm probably going to bite the bullet and spring for new liners, pistons, rings and bearings, as well as one new rod. Oh, and a new crankshaft. I have serious doubts as to the chances of regrinding the crank, reconditioning the rod and then finding a suitable bearing to fit it. One piston and liner looks pretty good, but the other two I really don't want to re-use. I don't know yet what caused all the damage, but when I put it back together, I want to know I have done all I could reasonably do to make sure things are right. I haven't yet pulled the camshaft, but I certainly hope it will look as good out, and it seems to still in place.

The hoped for “shortblock” isn't in stock and would likely take around 8 weeks to come in, so that's probably not gonna happen. A replacement engine is over $3000, so that's not gonna happen either.

-

December 20, 2012 at 6:24 am #35442

If we can help let us know, I have not seen any complete Short blocks for any of these chinese engines, unless someone gets a complete engine and starts removing parts to make a short block.We should have all the parts in stock for you to rebuild your existing block

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

December 20, 2012 at 10:19 am #35443

We have the complete blocks in stock or we have the bare blocks in stock also with all the parts to build if you go that way. We have every part for your tractor in stock. http://www.circlegtractorparts.com

Ben

Circle G Tractor Sales, Inc.

662-252-5272

-

December 21, 2012 at 11:56 pm #35444

rd, in post 57 you said you found a bread tie in one of the crank oil holes. Was that the journal that spun the bearing? If there were bread ties in the crank that would/could be a cause of bearing failure.

-

December 22, 2012 at 2:01 pm #35448

I can't say for sure which journal it was in. I was shocked to find it, and was absorbed in the process of figuring out how to get the crank out at that point (hadda pull the timing gears and gearcase off). I agree, that could certainly have been the cause of the spun bearing. I am also seeing signs of damage from what I think was either dirt in the engine, or casting sand left in the engine. I know the oil and filter was changed out at around 120 hours, and was told it had been changed out sometime prior to me buying it with 60 hours on it. Could be the air filter has been letting dirt or dust get past it, but don't yet know. Still need to get the cam pulled to see if there is damage there, as well as ensuring the bearings are aligned to allow full oil flow. I think it was okay cuz I do have oil to the valve train, but not as much as I had expected.

-

December 22, 2012 at 2:23 pm #35449

I believe it's no coincidence a bread wrapper tie found it's way from the dinner table into your crankshaft.

I'll speculate that bad crank throw and spun bearing are the handywork of an unscrupulus mechanic (and I use that term losely) using it under a bearing shell as a shim. I will further speculate there are no Chinese markings on the tie, and that the seller is not reputable. There are grounds for a lawsit here citing latent damage and misrepresentation with intent to defraud.

Account deleted.

-

December 22, 2012 at 4:27 pm #35451

I sold that tractor to Roger. It was my own personal tractor. The oil was changed when we got it new and again right before he bought it. The tractor was sold for two reasons. First: at that time my father in law lived with us (now diseased) and he had a heck of a time operating it. Also I wanted a bigger tractor as that 25HP machine would not cut the mustard on some things we needed to do. That's why I went to a 40HP machine. Other than that the machine was never touched.

When a person has been inside a large number of these machines that's when you really get a sense of the lack of quality control. We found a plastic screw on lid inside the transmission of one machine shipped directly to me from the factory. The worst was a brand new tractor that came in. They put just enough HYD oil in them to get it out the door. We drained that and filled it with new oil just to watch it run down the outside of the 3 point lift housing. The casting core had shifted so badly that the side of the case was less than paper thin. It actually had a pin hole in it. That should have never left the factory. The casting should have went to remelt.

Some casting sand still in the engine would not surprise me. I have seen worse.

Of course I am sorry that Roger is having these issues. Besides the pain in the ass of fixing it he is a very nice guy. There is more than one reason why I don't sell this stuff anymore. I got to the point where I could not put my name in it and be happy about it.

Larry

-

December 22, 2012 at 5:36 pm #35452

Bob, I can understand your reasoning, and if I was a spectator in all this, I might tend towards your line of thinking. But I remember when I went looking for this tractor, I called the dealer and asked about a new machine. At that time he didn't have one in stock and figured it would be a month or more before he'd have another in. I asked him then if he had or knew of a used one available. He said yes he had the one they had been using on the place, but his Father in law didn't get along well with the shuttle shift and he was gonna replace it. Can't imagine there would ha ve been anything hinkey with it if he was using it as his own personal tractor, and he didn't offer it to me. I asked him about it. All of which satisfies me the deal was all on the up and up.

Thanks for the kind words Larry. Glad to see you're still around, and would enjoy chatting/writing with you again, now that I am back on-line here.

We all knew, or should know, anytime you buy much of anything, it's a roll of the dice. Most times you come out okay, but once in a while, ya don't. In my lifetime, my wins have far outweighed the losses, so I figger the law of averages came to pay me a visit, lol. And Larry did right by me by sending me a new injector, twice. The second time was after the warranty period we had agreed on, had expired.

Anyway, to the good, I am forging ahead on this thing, and have a fair bit of confidence in it turning out okay when I get it back together. My only real trepidation involves making sure the timing is all correct. I'm pretty syre I have a full grasp of how it all has to be set, with #1 piston at tdc, and everything else should fall into place as far as the timing marks. The injector pump I am hoping, won't have changed it's setting with me unbolting the housing from the gearcase, and then realizing it didn't have to be. Time will tell, and if that's gonna be a problem, I reckon I'll deal with it when that time comes. Pulled the cam today, and to my untrained eye, it looks pretty good. I will post some pics later.

Larry, give me a shout on e-mail when ya get some time, let me know what ya been doing to keep from being bored!

-

December 22, 2012 at 7:29 pm #35453

Okay, first Iwent thru and measured all the bearing surfaces using the mm scale. Then I went to the inch scale and did it again. The last photo shows what I refer to as “the bread wrapper twisty-tie”. Found another small piece of it when I pulled the cam out. Anyway, to me the cam looks good, but if someone disagrees, I am anxious to hear your thoughts.

-

December 23, 2012 at 12:37 am #35454

Hi Roger,

I am not sure I have your email address anymore. You can email me at larry@cooljohnsons.com

The cam looks good from the pictures and I have no idea what that bread wrapper tie looking thing is ???

Larry

-

December 23, 2012 at 10:57 am #35456

It was probably put there by a pissed off Chinese worker. I'm sure there are a lot of them in China.

-

December 23, 2012 at 3:14 pm #35457

Well, now that I know the history behind the purchase I will retract my statements. Had I known those details earlier on I wouldn't have made them.

I think the cam looks good also.

The bread wrapper clip I thought you were referring to was the clip type, not the wire tie type. Sorry 'bout the confusion.

Account deleted.

-

December 23, 2012 at 3:37 pm #35458

The confusion is partially my fault. I don't get on here that often anymore. And when I do I only click on threads that sound interesting. When I saw “Engine Knocking” I thought another bad injector for someone because 99% of the time that's what it is. But when it kept showing up I thought… dang it's taking a long time to fix that and perhaps I should take a look. Only then was I up to speed on what's going on. I was completely out of the loop on that one 🙁

-

December 23, 2012 at 3:48 pm #35459

Bob, confusion would be turning that picture of bread clips into a jigsaw puzzle

-

December 23, 2012 at 4:30 pm #35460

I hadn't gone into the history of the purchase and what-not before because it didn't seem relavent to what was going on with the tractor. I still can't say for sure what caused the spun rod bearing, other than the “evidence” of dirt/sand/debris found in the lower parts of the engine. The bad liner for the #3 cylinder I am real certain was caused by water/moisture getting in during it's long sleep (still need to get that rain cap bought for it). The bad scuffing on the piston skirts and associated marks on the sleeve of both #2 and #3 are, I believe, caused by dirt.sand/debris. Possibly getting in thru a defective air filter. I'll be doing as someone suggested and replacing the filter with a Baldwin and re-configuring the mount and breather hose set-up. I still need to take all my injectors to a good diesel shop and have them tested to ensure I have 3 good ones.

I will grit my teeth tomorrow and call in my parts order. Then, after Christmas, I can get started cleaning all re-usable parts and cleaning old gasket material off.

-

December 23, 2012 at 5:32 pm #35461

The least painful part will be the raincap. Mine was around $9.00 at Napa if I recall. It's earning it's keep today. I left the tractor behind the greenhouse under clear skies last night, it's now covered in 6″ of snow and coming down hard.

Don't sweat what caused the rod bearing failure. The doctors still can't say for certain why my heart stopped, and I suspect my repair bill is just a little bit higher.

-

December 23, 2012 at 6:59 pm #35462

Yup, I had bought one for my old Oliver and it was reasonable. Never seem to remember to measure the pipe size so I'll know for sure what size rain cap to buy, lol.

Good point regarding the rod failure. I figgered if I can't discover why, I can't do much to prevent it again, other than keep the air clean, keep the oil and filter changed and hope for the best.

Lets have no more “heart-stop” episodes TB. There's cheaper, better ways to get a “rest-up-vacation'.

-

December 24, 2012 at 6:18 am #35463

Roger, we will be closed Mon. & Tues. for the holidays, please e-mail the order to me and I will get it priced up for you.If all is good we can Ship on Wed. the 26th

tommy@affordabletractorsalesco.com

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

December 24, 2012 at 8:20 pm #35466

I will suggest that you pressure wash the block real good including all the oil galleys.

-

December 24, 2012 at 10:57 pm #35467

Carl, I got me a brand new parts washer with a pump and everything. I'll wash everything thoroughly with that and use my air compressor to blow thru the passages to make sure the innards are all clean. But you're right, I want it all as clean as it can be, prior to the rebuild.

-

December 26, 2012 at 9:15 am #35470

does your exaust manf have a weep hole that might be plugged up?

-

December 26, 2012 at 1:54 pm #35471

Could be. Wasn't aware there was a weep hole in it, but I will surely check for it.

-

December 27, 2012 at 3:51 pm #35479

there should be one on a up swept exaust ,mine is in the elbow it is only about 1/16 inch hole,when I think of it I check mine if I walk by it when it is running.

-

December 27, 2012 at 9:12 pm #35480

I have a 254 and there is no drain hole in the exhaust manifold or elbow on mine. The elbow comes straight out of the exhaust manifold and goes up to connect to the muffler and exh. pipe. My exhaust pipe has a bend with a 90 deg cut to allegedly keep the water out. I keep my tractor in a pole barn but if I kept it outside I would cut the pipe off and put a flapper cap on it.

-

December 29, 2012 at 7:19 pm #35484

well others can chime in but I do not feel that it would not hurt anything to add a weep hole in the bottomside of the elbow,cause you never know unless you have the crystal ball I have been looking for.

-

December 29, 2012 at 7:23 pm #35485

Nope, shouldn't hurt a thing. I'll do that before I put mine back together, as well as putting the rain cap on.

-

December 30, 2012 at 12:25 am #35486

Since Cat, Cummins, Detroit Diesel. and Allis Chalmers didn't put drain holes in their exhaust manifolds, Kenworth Trucks decided to try them on the 90° exhaust fitting at the base of the stack(s). After one year of testing and observation it was determined that there was no cost benefit or maintenance saving, saying in effect they were more trouble to maintain than they were worth because they would clog frequently and expose untreated metal causing corrosion. That was the last I ever heard of it. 1974.

My dozer does not have a drain hole anywhere, nor does my skid steer, and personally I'd like to see all the exhaust go away from my smelling it. My dozer has a 90° and a slash cut tip, the skid steer has a 45° and a slash cut tip. If they were straight stacks they'd have rain caps. Period.

Account deleted.

-

December 30, 2012 at 10:14 am #35487

I guess as far as the manufactures thoughts go it depends which way the wind is blowing.

-

December 30, 2012 at 12:02 pm #35489

I was working at Truck R&D at the time. I was surprised at how much thought, time and energy went into such a seemingly trivial pursuit. But that's the way PACCAR is.

The wind can blow in any direction it wants to, but when it starts blowing fumes up my nose, it's time to change something.

Account deleted.

-

January 1, 2013 at 8:58 pm #35507

your nose must be great I can not get anything out of that little hole smell wise.what is your thoughts on weep holes in mufflers?

-

January 1, 2013 at 10:20 pm #35508

I don't know about Bob's sniffer but I don't think the little weep hole in mufflers do much good. I've had a few with weep holes and they lasted no longer than those without. Now days they use steel alloy that doesn't rust very much. In fact my 2003 Ranger still has the original exhaust system and it's still in real good shape. I don't think the muffler has a weep hole. I wonder if they still put them in the mufflers now.

-

January 2, 2013 at 9:54 am #35513

As I stated earlier, weep holes are a waste of time because they plug up. You are much better off by just placing a soup can or cut off water bottle over the exhaust pipe – especially if you leave it parked out in the weather.

As Carl said, with the improvement in aluminized metals, I think the condensate drains in mufflers are gone. I checked my F-350 diesel and there is no drain holes anywhere.

But, you can do whatever you want.

Account deleted.

-

January 2, 2013 at 4:25 pm #35517Happy

New Year to all! Most of the parts I had ordered on the 26th, arrived today via USPS. Still awaiting the crankshaft, which should be coming via UPS. THANKS, AFFORDABLE!!And so begins the rebuild process. I can get as far as assembling the pistons, rods, rings, sleeves, until the crank arrives. I have the block pretty well cleaned up and the old gasket material removed, thanks to

a wire brush mounted to my cordless drill. Yeah, I tried the old craping

routine, but decided the wire brush hadda be the better way. Blew out all the oil and water passages in the block, so there shouldn't be any sand, dirt, bearing remains left to muck up the works. Gotta remember to pick up some “stuff for checkin bearing clearances” (can't recall what it's called right now, dangit!) next time I am in town. Photos to come later. -

January 2, 2013 at 5:36 pm #35518

Your Welcome the crankshaft is also on its way, we build a wooden box to protect it.

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

January 2, 2013 at 6:09 pm #35519

Roger wrote:

“Gotta remember to pick up some “stuff for checkin bearing clearances” (can't recall what it's called right now, dangit!) next time I am in town.”

It's called Plasti-gauge.

Account deleted.

-

January 2, 2013 at 7:04 pm #35520

Lol, thanks Bob, I knew what it was called, but the ole memory banks just wouldn't give it out!

-

January 2, 2013 at 7:10 pm #35521

I knew that you knew. I need a jog every now and then too.

Account deleted.

-

January 8, 2013 at 9:06 pm #35549

Okay, UPS guy delivered the crankshaft this afternoon. So the project is back in gear. Got the mains installed and then the pistons, sleeves etc, installed and connected. Was preparing to torque things to spec, but I discovered my torque wrench had been left set at about 140 ft/lbs from the last time it was used. Annoys the crap outta me when I do something like that cuz I know better. So tomorrow, I go to town and find a torque wrench I can rent, as well as finding out where I can send mine to be re-calibrated. Oh well,

-

January 8, 2013 at 9:28 pm #35550

when you get the other torque wrench find a bolt that it real tight set the one to a couple different readings and compare the reading to the one you left loaded you might get lucky. you might be in the + – window.

-

January 8, 2013 at 9:53 pm #35551

when you get the other torque wrench find a bolt that it real tight set the one to a couple different readings and compare the reading to the one you left loaded you might get lucky. you might be in the + – window

Can someone please translate that?

Account deleted.

-

January 8, 2013 at 10:53 pm #35552

I could do that Dave, and I appreciate the suggestion. However I'd rather have my torque wrench calibrated to do what it's supposed to do, with an acceptable degree of accuracy. This is a long handled, ratcheting clicker type torque wrench, and I paid good money for it about 25 years ago. So it doesn't owe me anything really, and I'd rather have it checked over professionally.

-

January 9, 2013 at 12:17 am #35553

Just me but if I rented a torque wrench I was confident enough in to assemble my engine I'd be comfortable torquing a bolt down to several measurements and checking the calibration on mine, or am I missing something here?

-

January 9, 2013 at 9:57 am #35556

Think that one thru. If I set torque wrench 1 (tw1) to click at 100ft/lbs, and then check it with tw2, I only know tw2 clicks at some reading at or under 100ft/lbs. Or, tw2 may click at a higher setting only because I inadvertantly, actually tightened it to a higher value. But I have no way to be sure both set to 100 ft/lbs, and ONLY 100 ft/lbs. I also don't know if tw1 and tw2 both set the same at 50 ft/lbs. Or 150 ft/lbs. I can guess and I can assume. And that may be satisfactory, depending on your application. I just prefer a bit higher degree of confidence in the accuracy of my torque setting tools. Just one more step in stacking the odds in my favor, when I am doing a job I have never done before, and have had no special training for (right parts, right tools, right books-instructions, frequently will result in a right outcome).

-

January 9, 2013 at 11:01 am #35557

I agree with your notion of having your torque wrench calibrated – measuring tools are only as good as their calibration. Testing yours against another unknown one can do nothing more than confirm a superstition, but it can't provide real certainty. On stressed assemblies, torque really does matter, so do it right. You wouldn't trust a $9.95 HF digital caliper to measure journal clearances would you? Nope, you'd want a real, calibrated micrometer.

-

January 9, 2013 at 1:50 pm #35558

I have a Snap-On 1% accuracy torque wrench that I use.

Snap-On Tools can check torque wrench calibration for you.

Like Rich says; Correct torque is very important.

Account deleted.

-

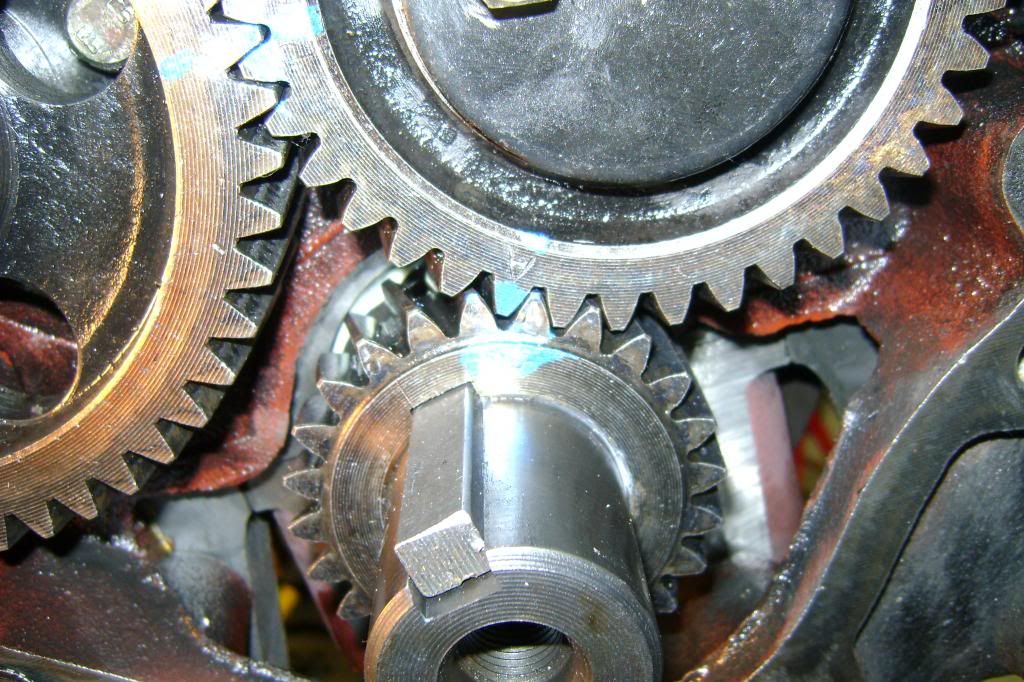

January 10, 2013 at 6:06 pm #35579Okay, I had some issues after I put the crank in and the pistons etc…..was preparing to work on gettin the timing gears and all installed, and discovered the crank etc seemed to be bound up. This was after I had done all the torque stuff and knew they were set a-right. I also knew if it wouldn'tturn over at this point, it was trouble and I had to take some backward steps and find where I made an error. My earlier pics came in handy cuz lo and behold, I had put the main caps

in wrong, and the pistons/rods were also in reversed. I discovered this after I looked at my earlier photos, and noted, the arrow on the main caps were pointing AWAY from the oil pump. I had installed then with the arrow pointing towards the right side of the engine, towards the oil pump. Okay, so I pulled the mains caps off, swapped ends and re-installed them, pulled the rod-caps, pulled the pistons/swleeves and rotated them 180 degrees, and re-installed. When i was re-torquing it all down again, I made another rookie mistake but caught it. When

you are pulling the torque wrench for the final setting, get the bolt snug enough so you can take it to final with one complete pull till it clicks. Otherwise, you'll almost certainly get it set too tight.Anyway, after all that, and liberal applications of oil, in addition to the assembly lube, it turns over now by hand, though it's still tighter than I had expected.So anyway, on to installing the timing gears. Note, I used some of the ex's metallic blue fingernail polish to mark the gear meshpoints for easier viewing etc. Woulda used white, but she didn't leave any of that, lol. The blue worked

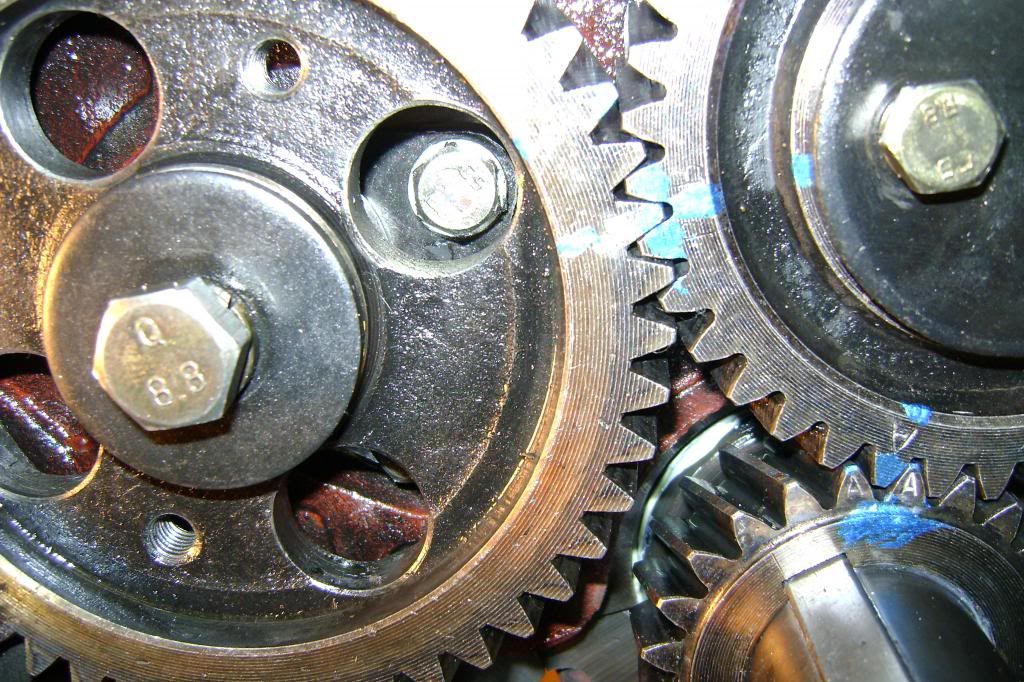

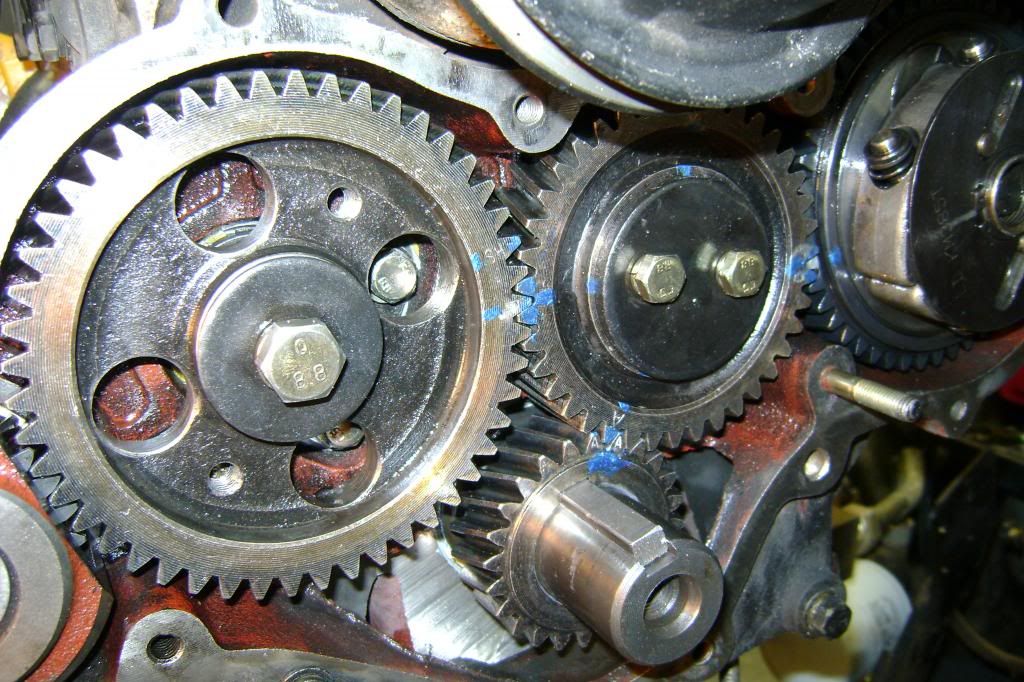

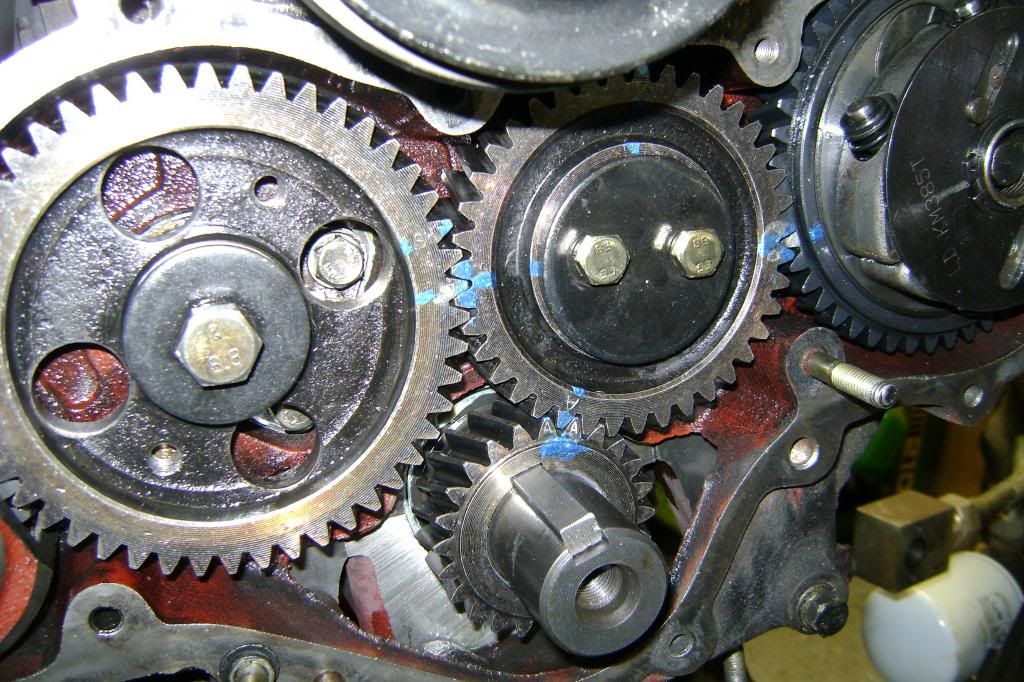

The crankshaft gear, has an “A” on one tooth, which corresponds to the idler gear and it's 2 teeth with “A”s . The injector pump advance gear has two teeth with “O”'s, whicj correspond with a single tooth on the idler gear, with an “O” on it. The cam gear has a tooth with a “B” on it, which corresponds to two teeth on the idler gear with “B”'s on them. This can be a little tricky to get it all to line up, but with patience, you will get it done.

The crankshaft gear, has an “A” on one tooth, which corresponds to the idler gear and it's 2 teeth with “A”s . The injector pump advance gear has two teeth with “O”'s, whicj correspond with a single tooth on the idler gear, with an “O” on it. The cam gear has a tooth with a “B” on it, which corresponds to two teeth on the idler gear with “B”'s on them. This can be a little tricky to get it all to line up, but with patience, you will get it done. Crankshaft gear meshing with idler gear

Crankshaft gear meshing with idler gear idler gear meshing with injector pump advance gear.

idler gear meshing with injector pump advance gear. Idler gear meshing with cam gear.

Idler gear meshing with cam gear.

View of one of the mounting bolts for the injector pump. When I was disassembling the engine, I was trying to get the timing gearcase off and couldn't see clearly how to get it to come apart. I knew the crankshaft gear hadda come off, the idler hadda come off and the camshaft gear hadda come off, and it looked like the gear for the injector pump hadda come off too. To that end, I loosened the pictured

View of one of the mounting bolts for the injector pump. When I was disassembling the engine, I was trying to get the timing gearcase off and couldn't see clearly how to get it to come apart. I knew the crankshaft gear hadda come off, the idler hadda come off and the camshaft gear hadda come off, and it looked like the gear for the injector pump hadda come off too. To that end, I loosened the pictured

nut, as well as the other two, but was unable to pull that darned gear off. Well, in looking things over more carefully, I noted one last bolt on the gearcase, and with a little judicious tapping with a brass hammer, the gearcase did begin to loosen. I knew I had screwed up by loosening those three nuts, so I looked it over carefully and could see where the pump assy had rotated from it's original setting, and I am hoping by simply resetting everythig back to where it was (fingers crossed), I can get it set close enough to get it eventually run

without doing any damage.

Nother view of the nuts. Note there is a slot which allows the pump to rotate, for setting the injector timing. I sure hope I get it put back where it originally was!

Nother view of the nuts. Note there is a slot which allows the pump to rotate, for setting the injector timing. I sure hope I get it put back where it originally was!At this point, I'm gonna take a long break and give you guys an

opportunity to ask questions, offer critiques, give advice, issue warnings, and so on. I don't want to move forward just yet, untill I have some assurance I'm not gonna hafta go back and un-do something due to a mistake.As an aside, any of you who haven't yet done so, go buy yourself a good quality head mounted LED flashlight. Dang, I did a lot of work on this project, fighting with flashlights and worklights and so on, till I remembered I had one of them lil headlights in my tool cabinet. Man, what a difference! Sure makes some of them “3-handed” jobs a lot easier if ya don't hafta hold a flashlight, or mess with adjusting a worklight all the time.

Read more: http://ctocf.proboards.com/ind…..z2HcIx2hBZ

Read more: http://ctocf.proboards.com/ind…..z2HcIEiJUS

Read

more: http://ctocf.proboards.com/ind…..z2HcFF2cVN -

January 11, 2013 at 10:39 am #35583

Always rotate the crank a little when installing and torquing each main cap and rod cap.

When torquing pull steady until it clicks and STOP. Do not jerk on the wrench or try to pull it real fast. When checking the torque loosen the bolt and re-torque it to spec. If you want to see if it was loose or tight then mark where one of the hex edges is and then loosen and re-torque to spec. Then look to see if the mark is before, at or past the mark. You have to mark the hex and the surface the bolt is against.

Have fun.

-

January 12, 2013 at 6:23 pm #35587

Hit another stopping point. To get right to the point, I ain't certain I put the new pistons in oriented the right way, with respect to the valve indent. I thought I had made sure to assemble them the same way as the old ones, but once I set the head in place and looked it all over, I am not so sure. In the attached photo, I am at the front of the block, looking towards the back, valve indent to the left, towards the exhaust side. The engine manual talks about it, but with the chinglish, danged if i know up from down. See attached photo

-

January 12, 2013 at 8:46 pm #35588

Can you tell by looking at the head or doing a rough measuring estimate?

ronjin

-

January 12, 2013 at 8:55 pm #35589

I looked at the head, and thought I was right since the valves seemed slightly closer to the exhaust side. But once I put the head in place, I noted the head is also slightly offset to the exhaust side. So I still am not sure.

-

January 12, 2013 at 9:04 pm #35590

Hmm…I went and looked at things again, and I'm thinking what I had called a valve indent, is maybe actually a space for the fuel to be squirted. If so, then I have the pistons in 180 out. The pisser is, I'm confident the rods are oriented right, so this means I will have to separate the rods from the pistons, etc, etc, etc.

-

January 12, 2013 at 9:17 pm #35591

Dang, one thing I don't have is a borescope, if I did I would look at mine and let you know what I see.

-

January 12, 2013 at 9:19 pm #35592

Here is a pic, the piston heads are 180 out, sorry to say

Here is a pic, the piston heads are 180 out, sorry to sayTommy

Affordable Tractor Sales

“Your Jinma Parts Superstore'

-

January 12, 2013 at 10:20 pm #35593

Thanks so much Tommy, at least I know now and can get back to making things right. Dangit.

-

January 12, 2013 at 11:16 pm #35594

Tommy, on one side of the rod is some numbers/markings, on the other side, nothing. Which side is oriented to the front, or does it matter. I know the rod and it's cap can only go one way, but does it matter which way the assembly is oriented?

As you can tell, I am questioning my recollection on how it came apart, since it was several weeks ago. Also, I'm gonna need another sump gasket cuz I can't salvage this one. Oh, I probably could, but who wants to deal with leaks after all this. You should have my card number.

-

January 13, 2013 at 1:51 am #35595

Rule #1 when disassembling machinery – make witness marks (thought you did that, sorry). Some people use center punches (one punch on each piece, two punches on each other piece, etc. (real handy on rods & caps)). I use a straight chisel to make an “X”, but I also use alpha-numeric steel stamps.

Tommy is correct. The swirl chambers in the piston crowns face the side where the injectors are, and are almost always opposite of the camshaft.

If there are markings on the con rods & caps, those marks usually face AWAY from the camshaft.

Account deleted.

-

January 13, 2013 at 8:44 am #35597

Bob, I did make witness marks on the rods. But that was several weeks ago, and at the time I had made them, I hadn't paid much attention to the markings on the main caps. Once I got focussed on those main caps, i marked them as well, and thought I had marked them with the same orientation, and the arrows pointed towards the left side of the engine. Well, my photos proved that to be mistaken so I put them back the way they were when I removed them. Once I made that mistake, I began to question whether or not I had actually marked the rod caps on the same side as the mains were, and so on it goes.

I had a series of strokes about 3 1/2 years back, and since then I've made a nearly full recovery. However I have also experienced occasions when my memory isn't quite up to par. More than once, something I was absolutely certain of, proved to be not the case, and this rebuild is a case in point. And that's why I am pausing and asking a lot of questions as I go along here. I had planned to have my replacement parts ordered and on hand before I did so much dismantling, but of course, that didn't work out quite that way. It's okay, I'll muddle thru and get this tractor back together and running right. I think I've now gotten past the point where my recollections will matter so much. God gives us challenges to grow us and teach us, and so I press onward.

-

January 20, 2013 at 8:24 pm #35714

well now that you have had time to reflect do you believe that that plastic bread clip had restricted a oil passage or was something else the cause of the bearing failure.

-

January 22, 2013 at 10:17 pm #35721

I do believe that whatever it was did play a big part in the bearing failure. I also believe the original engine assembly process was less than ideal in that it seemed like a lot more dirt in that engine than the hours on it would cause.

On a brighter note, I finally got it all back together today, checked everything over (no left-over hardware), and refilled the radiator and the crankcase. I locked the engine kill with vice grips and spun the engine over long enough to build oil pressure and purge the fuel lines. tightened the lines up again, released the engine kill, gave it about 10 second of pre-heat and cranked it over. 3 time over it fired and then kept running. Smoked like crazy for a minute or two then cleared and began running smoothly. checked ot over and the only leak I have now is one up by the steering cylinder. I'll address that tomorrow, then take it outside so I can let it run a bit longer and check things over some more. I also know it moves and the loader is working, so i am hopeful.

-

January 22, 2013 at 10:58 pm #35722

I do believe that whatever it was did play a big part in the bearing failure. I also believe the original engine assembly process was less than ideal in that it seemed like a lot more dirt in that engine than the hours on it would cause.

On a brighter note, I finally got it all back together today, checked everything over (no left-over hardware), and refilled the radiator and the crankcase. I locked the engine kill with vice grips and spun the engine over long enough to build oil pressure and purge the fuel lines. tightened the lines up again, released the engine kill, gave it about 10 second of pre-heat and cranked it over. 3 time over it fired and then kept running. Smoked like crazy for a minute or two then cleared and began running smoothly. checked ot over and the only leak I have now is one up by the steering cylinder. I'll address that tomorrow, then take it outside so I can let it run a bit longer and check things over some more. I also know it moves and the loader is working, so i am hopeful.

-

January 22, 2013 at 11:17 pm #35723

Hey, that's great news, Roger! Congratulations on a successful completion of a pretty daunting task.

-

January 23, 2013 at 9:34 am #35726

Great Job on the rebuild, hopefully we did more than just provide your parts, we also tried to offer you any Tech support we could .This board is a great souce of information also.

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

January 23, 2013 at 9:37 am #35727

Like many of us, I was reading this topic with great interest and all I can say is well done Mr. Stevens You took on a difficult task and you accomplished your goal… congrats!

-

January 23, 2013 at 11:47 am #35728

Job well done Roger.

It's analogous to cutting your own firewood – it warms you twice.

Account deleted.

-

January 25, 2013 at 3:05 pm #35544

Roger,

Glad this worked out as it did. And again it was my pleasure to provide advice as needed. Pat yourself on the back you did the work.

-

-

AuthorPosts

- You must be logged in to reply to this topic.