Forum › Forums › Tractor Implements › My LW6 backhoe arrived today!! HELP

- This topic has 139 replies, 10 voices, and was last updated 10 years, 5 months ago by

Ben1941.

-

AuthorPosts

-

-

August 3, 2011 at 1:00 pm #30370

My LW6 backhoe for my Kioti LK3054xs 2004 model. The BH is in a crate so i guess there's a lot of putting together to do!

I have it out of the crate,what's the best way to start putting it together?

The Hyd. fluid tank was empty when delivered.What type of fluid should i use?

It did not come with a PTO shaft,the seller said the pump bolts up to the PTO. I can't see how i can do that…

I don't see a place for the center arm of 3 point hitch on BH.

There's not much info in the manual that came with it.

Appreciate all the help i can get..

There's pics. of tractor PTO in Photo Album!! couldn't post them here…

Hope to do it right the 1st time

Thanks

Ben………

-

August 3, 2011 at 5:14 pm #32837

Was your dealer aware that your tractor was NOT a Jinma? Your tractor MAY have a four-bolt plate just above the splined PTO shaft that covers the tang drive for the PTO pump – this is where that pump would attach. If you don't have that cover plate then you will have to either plumb the hydraulics off of the tractor's system or get a Prince PTO pump.

The “center arm” or adjustable top link you are referring to attaches to the seat support. Just below the seat are three or four holes for that purpose.

You are going to want to flush the hydraulic system and give the reservoir a thorough cleaning before putting the hoe into service. You will want to use ISO AW 32 hydraulic oil which is available almost everywhere.

You're on the right track Ben.

Account deleted.

-

August 3, 2011 at 8:15 pm #32840

Hi Ben,

Here's a link to maybe a better manual than what you have.

http://www.pegasus-industries……ackhoe.pdf

My LW7 backhoe has a pto pump gearbox that slides on the tractor pto shaft and is held in place with chains.

Make sure that all your hydraulic hoses are connected properly!

Have fun putting it together!

-

August 3, 2011 at 8:57 pm #32841

Thanks Bart,

That's way ahead of the manual that came with my BH……no pics. or illustrations in mine…..

I'll take a closer look at the pump tomorrow,looks something like that,but don't have that piece like a pipe sticking out!

“OH ME NERVES”

Thanks a million

Ben……….

i'm reading……..

i'm reading…….. -

August 4, 2011 at 2:22 am #32842

Ben,

That “piece of pipe” is an internally splined hollow shaft that slides over your existing splined shaft. That pump setup uses an overdrive transmission (gearbox) that allows the pump to change direction of rotation and run at engine speed when your PTO is engaged in the “540” position. Yes, the hoe will have to be fully functional to perform this. Do not run the pump dry or deadhead it.

I'm not familiar with your tractor so it may not have the provision to mount a tang drive pump after all. Looked at your pics and you may have that mounting buried underneath the bracketry.

Account deleted.

-

August 4, 2011 at 4:47 am #32843

Good Morning,

6:30 am and anxious to get back at it..Bought this 04 Kioti Lk3054 tractor with 530 hrs July 14th/2011..so i'm just getting the hang of it..

No center link came with it,i'll try to get one when the parts place opens,i ordered a manual for the Kiota,but won't have it for 3 weeks…so some of my questions may sound dumb

When i get the BH together and fill the tank with fluid,do i have to prime the pump and lines,if so how? Have to find a way to get the pump on the PTO first tho!

Do not run the pump dry or deadhead it.??????????

Bear with me…..or BEER with me if i get it set up and working

Thanks

Ben

-

August 4, 2011 at 9:59 am #32844

Do not run the pump dry or deadhead it.??????????

Yes, that is correct – do not do those tings or you will b e buying a new pump almost immediately.

If you run the pump with no fluid in the reservoir and pump, the internals of the pump will be trashed in short order. The suggested method is to fill the sump with oil, then pour some oil in the pump itself (through the outlet and/or inlet) and then start it up slowly to give it time to purge the air form the system. Note that this is for an open-center system – a closed center system would probably have different guidelines but I don't know them.

Deadheading the pump means running the pump with the outlet blocked – this can happen if you have quick-connect hoses and the outlet hose is not connected or the connector has an internal failure so it doesn't open when connected to the other half of the connection. The pump will be trying to pump the fluid against complete resistance and thus trying to compress an incompressible fluid. The case of the pump and/or the seals will be blown out. If the seals are blown out they can be replaced,but if the case splits you're screwed.

One of the most common hydraulic pump deadheading scenarios is when someone takes the FEL off their tractor and fails to hook the hoses from the pump to each other. With the hoses open, the ball checks in the connectors are closed and the fluid has nowhere to go so it deadheads the pump and blows it up. Only take a few seconds of run time to do this, too. You don't get a warning, in other words.

-

August 4, 2011 at 10:44 am #32845

Thanks for that Rich!

I'm so green at this it's almost funny ..

Finished hooking up arm and bucket,working on stabilizers and hoses now……

Sure i'll have more questions very soon.

Thanks everyone,i'd be lost without you!

Ben…….

-

August 5, 2011 at 3:16 am #32847

Ben,

If it helps you, here is a picture of the back of my Jinma284.

The darker rectangle plate with 4 bolts directly the covered PTO shaft is the cover for access to the auxiliary PTO connection that Bob Rooks mentioned. My JW03 backhoe connected here rather than on the PTO shaft and I believe that most of the Chinese backhoes did.

RonJ

ronjin

-

August 5, 2011 at 3:39 am #32848

Ben,

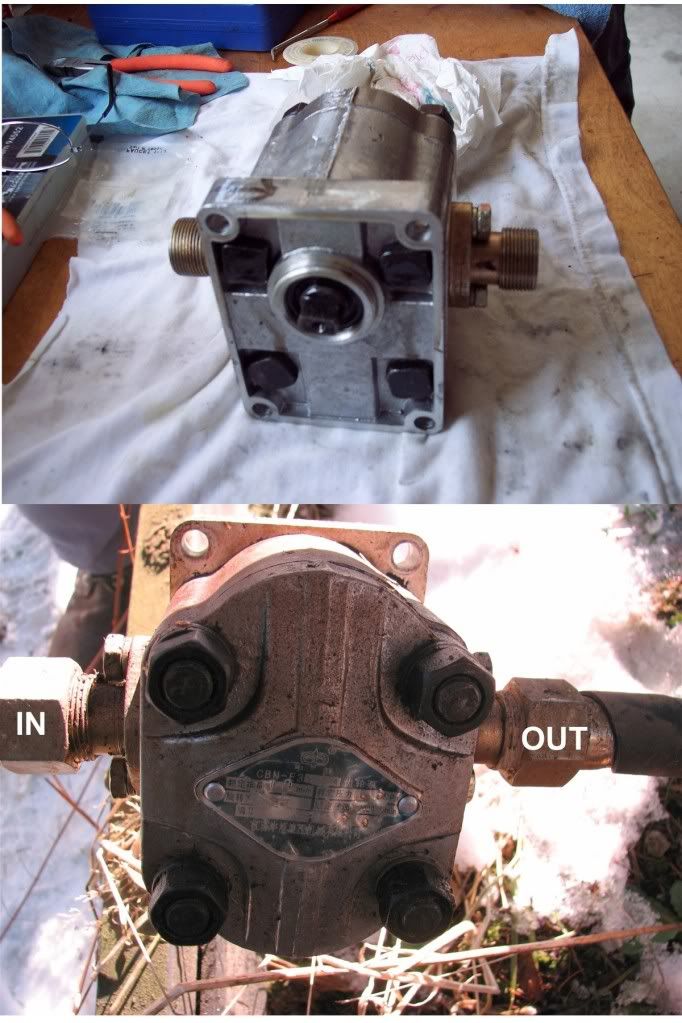

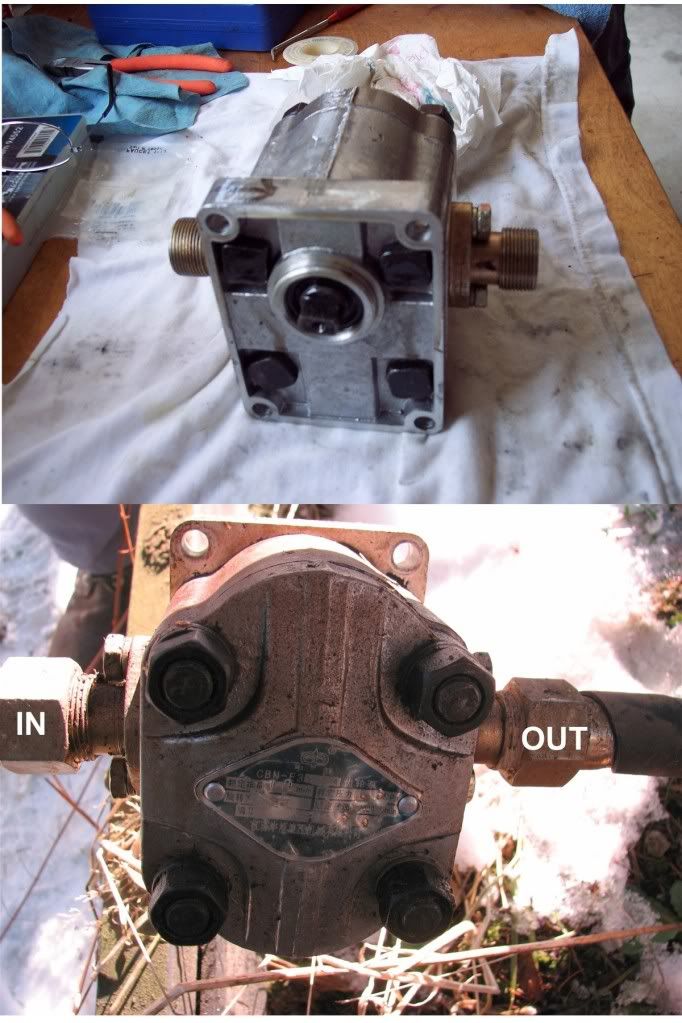

Here is a picture of the front and back of the hydraulic pump.

RonJ

ronjin

-

August 5, 2011 at 11:55 am #32850

Hey Ron,your reading my mind

Trying to figure out a way to install the pump to the PTO…

Here's what i was trying to do….thought i'd check the site to see if i had any more tips…and there you were..lol

I removed the hood it's a weather cover over the PTO….Cut out a piece of metal about 8x10in. ..drilled out the holes to fit the pump…now if i drill 4 more holes to where i removed the hood i could bolt the pump to it..

The pump looks the same as yours…………I try to post a few pics when i get the holes drilled out..

I put the BH together on the floor,don't have it hooked to the tractor yet,waiting on my son to come back from the city with the center link and some 3 pt.hitch pins…… I'picked up 5 gal. ISO AW 32 so i'll fill tank and prime pump and lines if that's possible,before i try it…

Back at it now….Got my fingers crossed it will work out ok!!

Thanks Very Much

Ben……….

Is the 3 pt. hitch the only thing holding the BH? ??

My son arrived..WRONG PART…150 mi away ..Link to big for my tractor!!

-

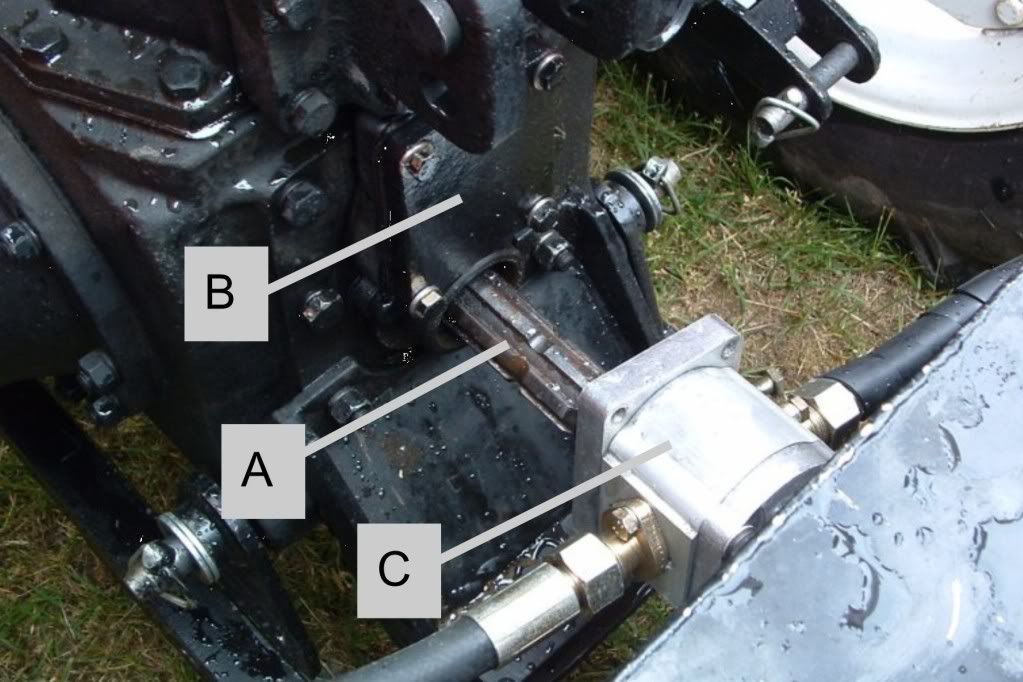

August 5, 2011 at 3:26 pm #32851

Ben,Not sure if we are communicating, so let’s try again. I have the Jinma 284 with a JW03 Chinese backhoe.

A is the PTO shaft that is not used for this backhoe.

B is the 4-bolt cover which covers a slotted shaft for the Auxiliary PTO.

C is the CBN-E3 pump which attached in place of the 4-bolt cover and into the slotted shaft.

RonJ

ronjin

-

August 5, 2011 at 4:47 pm #32852

No way to bolt pump up to PTO the way it is ,so to keep it in place i removed the hood that was there and cut out a piece of metal,bolted it to the pump,have to drill 4 more holes and bolt it to where the hood(cover) was.. so it will keep in place …very rough fix indeed!

Looking at my tractor from the rear,it's not the same as yours and the pump looks different …………I have a LK3054xs Kioti and a LW6 china BH.

Sorry if i'm not making myself clear…..it's all new to me..

Appreciate you trying to help,if there's anything else you can think of

let me know…………

There's no PTO shaft with the BH.

Posted a few pics ..

Thanks Again

Pics. didn't show………….I'll try again!!!!!!!!!!!!

Ben……

-

August 5, 2011 at 5:18 pm #32853

Ben,

Does you pump look like this? What is the number on it? If it is a CBN series, it will not go directly onto the tractor PTO shaft.

Does the back of your tractor look like this with a 4-bolt plate above the PTO shaft?

If it is a NO to these 2 items, you will have to tap into your tractor hydraulics to use the hydraulic pump that already exists on the tractor or get a pump that will actually mount on the PTO shaft as I think that Bob Rooks already mentioned.

RonJ

ronjin

-

August 5, 2011 at 5:29 pm #32854

Ron,no,no..not the same………

My pump fits over the PTO,but i'm trying to attach it to something to keep it in place..

I couldn't get pic. here so there posted in Photo Album…also pics of the rear of my Kioti tractor..

Model# on pump–CBN-3

Thanks

Ben……

-

August 5, 2011 at 7:47 pm #32856

Ben,

I can’t tell for sure which photos in the album are yours, but if I’m looking at the correct ones –

Your pump mounts to a reddish colored adapter that then slides over the PTO shaft. Correct?

When the PTO is engaged there is a tremendous amount of rotational pressure on that pump. This requires bars or chains to prevent it from swiveling. A piece of sheet metal will not hold it.

I will need to let someone else walk you through that.

RonJ

ronjin

-

August 5, 2011 at 8:55 pm #32857

Ben,

This is how we modified our pump gearbox to be securely attached to the PTO on our Jinma 454.

-

August 5, 2011 at 11:03 pm #32859

Thanks for reply Ron and Bert.

I don't know where all the pictures are going that i uploaded ….try it one more time.

Seems like i can only get them in Photo Album,the first 6 or 7 are mine!

OK,finally got the pics ….

What i was trying to do,bolt piece of metal on to red part of pump where spline goes in…slide over PTO drive..then bolt on with the 4 bolts that came from the cover that i removed…I don't have the 4 holes drilled in the metal yet that will bolt into where the hood was removed.

Do you think with a heavier metal,this would work,if so i'd get the welding shop to make up a plate for it?or maybe do something like Bert got there…….

Ron said: Your pump mounts to a reddish colored adapter that then slides over the PTO shaft. Correct? Yes …

I'll check it out in the morning and see what can be done with it!

Hope you can make some sense of what i'm trying to explain……..

Good Night and Thanks!

Ben

-

August 6, 2011 at 7:39 am #32860

Ben,

What the others are talking about on the mounting of the PTO pump is a torque limiter – a means of keeping the pump assembly from rotating when the PTO turns and the hydraulic pressure makes the whole pump want to spin around. There's nothing magic about this. Most guys just use a piece of chain or a steel bar to connect the pump's gear box (the red part) to the tractor frame. Something as simple as a piece of 1/4″x1-1/2″ flat bar about 16″ long that is bolted to the gear box and sticks out far enough on one side to hit against the drawbar frame would do the job fine. So would a chain. Your sheet metal might work, if it is heavier than about 3/32″ thick. If it is too thin it will get twisted up when the pump is under load and allow the pump body to turn and damage your hoses.

-

August 6, 2011 at 8:46 am #32861

That sounds like a better way to do it. I'll have another look at it.Something like pic in Berts post…..

OK,you bolt it to gearbox,do you also bolt to draw bar frame,guess so, to keep it from slipping of PTO.

Thanks Again Rich.

Ben…………..

everything…..

everything….. -

August 6, 2011 at 10:17 am #32862

Generally, the hydraulic lines are stiff enough to keep it from slipping off the PTO shaft, but something to hold it there wouldn't hurt – a bungee cord or piece of chain would do fine, I think.

Half the ones I've seen with a torque bar for the anti-rotation the guy just

used a pair of ViseGrips to clamp it to the drawbar, or let the torque

keep it there. (grin) I'm not saying I recommend that, of course! -

August 6, 2011 at 11:27 am #32863

Ben,

There are 2 requirements that need to be satisfied.

1- The gearbox/pump needs to be fastened so that it will not slide off of the PTO shaft. I don't believe that the hydraulic hoses by themselves will do that.

2 – Gearbox needs to be fastened so that it can not rotate.

Bert's fixture satisfies both those requirements and there are other methods of doing it also.

Bob Rooks – where are you?

RonJ

ronjin

-

August 6, 2011 at 1:37 pm #32864

Good,something i can do..i'm just going to block it for now and use a chain to keep it steady…temporary fix,so i can pump fluid to the hoses ..make sure there's no leaks etc.

Tank full..THE PUMP..to prime just pour fluid where the hose connects?There's a plug on top the RED gearbox it's dry do i put the same fluid in there??..guess i should stick with woodworking……

Wish there was a good manual with this BH..No mention of the pump..

I won't be using it for work or anything.until i get the pump secured.

Have to wait”til Monday to get some brackets made up..

If anyone has any pictures of the way you did it,love to see 'em

Bob Rooks – where are you? Out in the shed!! lol

Near St. Johns,Newfoundland

Thought you meant me……….lol

Wish someone could drop over and set this up for me…

Thanks Much…………..

Ben……….

-

August 6, 2011 at 6:26 pm #32865

Hi Ben,

Don't do anything more 'til I get back in a couple hours. So far so good

Account deleted.

-

August 6, 2011 at 7:48 pm #32866

OK,Your Late…………

Must be on your way to my place….lol

-

August 6, 2011 at 11:05 pm #32867

Ha ha,

Had to get to work – night shift.

Anyway, be careful about mounting the transmission/pump assembly rigidly to the tractor as in Bert's pics. Rigid mounting doesn't allow for any misalignment and can put undue lateral stresses on the PTO shaft bearings unless perfect. My Prince pump just “floats” on the shaft and is held in place by the reaction (torque) chain, which for this type of pump is all you really need. Do not attempt to operate the pump without some sort of reaction device otherwise the hoses will instantly turn into black spaghetti.

When you engage the PTO make sure you put it in the 540 position. I recommend that you have the engine at low idle. Watch the level in the hydraulic reservoir as you cycle the hoe functions and top up as needed. You want to do a final oil check with all of the cylinders retracted.

Good luck.

Account deleted.

-

August 7, 2011 at 7:48 am #32868

Bob,gotta do something with it today,i have 4 steel brackets made up to go from the gearbox (the red part) to the 4 hole where the weather hood came off,hood won't fit now with the pump there..I think this will work ok!

My son picked up the center top link for 3 pt. hitch,but it was to big,so i'm hoping to have the right one delivered tomorrow..

Question i asked before,don't think i got answer: Is the 3 pt. hitch the only thing holding the BH???? My first tractor with BH….

The plug on top of PTO pump gear box Is that where you prime the pump?????

It's so foggy and cold here you wouldn,t be able to find your way anyway!!

Thanks everyone for all the advice!

Ben……………

-

August 7, 2011 at 9:10 am #32869

Ben,

Yep, the TPH is the only thing holding the backhoe, unless you go to a frame-mount hoe set-up. You need to keep that in mind when deciding how hard to work the hoe. That hoe is probably small enough that it won't destroy the TPH even if you do get vigorous with it, but why take a chance? Sometimes it is good insurance to just rent a Case 580 or a track hoe when you have big work to do.

The plug on the top of the PTO pump's gear case is where you lube the gear case. I'd guess it uses something like 80W90gear oil, but others would know better. It is not where you prime the pump – you'd do that through the pump inlet hose,if necessary. However, if your hydraulic sump for the hoe is above the level of the pump it will prime itself, just run it slowly at first with the outlet hose disconnected and put to run into a bucket. As soon as you get flow, shut down and hook up the outlet hose. You should be ready to go, I think. As previously noted, I don't have a backhoe so others will know better than I do.

Foggy and cold? You can keep that, thanks! I hate cold.

Rich

-

August 7, 2011 at 9:59 am #32870

Thanks Rich,

I'm beginning to see the pitcher,should be able to test it tomorrow!

Please someone tell me what kind of oil to put in the RED gearbox that goes on the PTO attached to the PTO pump..it's dry so i need to put something in there before i start it up…..Have no manual on the gearbox or pump…

Enjoy the sunshine….whatever that looks like!

Thanks Everyone

Cheers

Ben…………

After a lot of trial and error I finally got the pump attached ,it's not a professional job,but best i could do with the little knowledge and tools i have.

Here's a few pics…please be kind ..lol

My wife just got back from church,she must have been on her knees praying for me,while i was on my knees swearing on that PTO thing! God Love Her!

-

August 7, 2011 at 11:13 am #32871

Here it is..a bit rough,but seems like a very solid install..maybe i'll add a chain just in case!!

PTO gearbox filled with 80W90 gear oil..ok i hope………..

BH tank took 5 gal ISO AW32 so far…

Thanks Again

Ben……..

Everybody must be in church!

God Bless You All………..

-

August 7, 2011 at 4:29 pm #32872

That will probably work Ben – my only concern would be that it doesn't allow the pump assembly to “float” on the PTO shaft to accommodate little alignment issues. Just keep an eye on it to make sure it hasn't gotten knocked off of true and it will most likely be fine.

If you see any tendency on its part to shift around any you might want to switch to the chain like Bob Rooks uses – I'm just a mite leery of anything “rigid” that doesn't have to be and chain allows the assembly to shift around freely to seek its own alignment but not fall off or torque around and scramble your hoses.

The 80W90 gear oil will be better than none at all, I guarantee that!

Looks like you're well on your way to having a back hoe.

-

August 7, 2011 at 7:11 pm #32873

I’m using phone right now. You will have to revise your mounting brackets.

Account deleted.

-

August 7, 2011 at 8:51 pm #32874

I have it attached,but i didn't start the pto yet.

Guess i.ll have to go with the chain and bar

Should have known better,after reading the post over and over

Give me your way of doing this,when you get time!!

Thanks everyone for your patients!

-

August 7, 2011 at 9:12 pm #32875

In my case I slide the gearbox on the PTO shaft and once correctly aligned it attaches or clips itself securely on to the PTO shaft and you can't remove the gear pump from the PTO shaft without pulling on the release mechanism on the neck adapter of the gear pump that attaches to the PTO. Once the gear pump is securely attached to the PTO, I then mount the bracket properly.

Ben, when you slide your gear pump on your PTO shaft does it secure itself to the point where you can't remove the pump from the PTO shaft without pulling or pressing on a mechanism to remove it?

-

August 7, 2011 at 9:25 pm #32876

Bert,the gearbox and pump slides on and off very easy,there's nothing else to pull or press to slide it in or out off PTO spline!

Better to be safe then sorry.

Thanks Again

Have a Good Night!

Ben………….

-

August 7, 2011 at 9:52 pm #32877

OK. Without going into a lot of detail, you should “X” the brackets from the upper two bolts on the transmission to the upper thread bosses on the tractor (where you have them attached now), or from the upper bolts on the transmission straight down to the lower thread bosses on the tractor. The brackets should be a minimum 3/16″ thick. This is necessary because eventually you will be demanding 20+HP and a couple hundred foot-pounds of torque from this pump.

Account deleted.

-

August 8, 2011 at 7:35 am #32878

Do Bob mean just put 2 brackets and cross them??

OK,think i got it………………

Use only 2 brackets..Right??

-

August 8, 2011 at 9:32 am #32879

Ben, re-read myth post. Two brackets “X” at top or two vertical top to bottom. You have to keep the fulcrum point as far away from the shaft CL as possible. Jeez I hate doing this on a phone.

Account deleted.

-

August 8, 2011 at 10:09 am #32880

Thanks Bob!

Any idea what type of bracket i need to move this berg from the back of my shed?

Just kidding!

No wonder it's so cold here!

This is what they make iceberg vodka and pure bottled water from!

-

August 8, 2011 at 9:25 pm #32881

That's cool!

A lifetime supply of Hawaiian shaved ice.

How long has that been there?

Account deleted.

-

August 8, 2011 at 9:49 pm #32882

That's just a piece of the massive iceberg, originally about 250 kilometres by 250 kilometres, that broke off a Greenland glacier..

Looks like that one is grounded,there about 2 weeks!

The most icebergs we had in years,most of them broke of the big one!

My relatives in Oklahoma would love to have that in their back yard!

Should have the BH up and running tomorrow..gotta break that berg up.Ha!

Have a good Week

Ben…………

-

August 8, 2011 at 11:01 pm #32883

For reference, here is a visual depiction of my recommendation.

Use either the blue or violet configuration – not both.

Account deleted.

-

August 9, 2011 at 10:16 am #32885

I think the violet is prettier than the blue.

-

August 9, 2011 at 3:43 pm #32890

I've been watching this closely because my own HW03 BH will arrive next week. I'm mostly interested in the hoe setup, flushing etc.

Relative to the bracket for resisting the pump torque, I don't want to interfere with Bob's excellent advice; however, some thoughts are as follows:

- It seems like a stout bracket could attach to two of the four bolts that are set back from those four closest to the PTO inlet. The bracket would attach to any two that are one above the other via longer bolts to accomodate it. If the bracket was perhaps 3/8″ thick X 1″ width and then enough length to fit up between the top lift mount “ears”, it would be stout and have long leverage.

- By forming the bracket with two offsets it might do the job. The first offset is to angle it or jog it “hockey stick like” , then a “return” to bring it directly under those ears. Then a second offset would bring it closer to the tractor and make up for that space. It could be first made from carboard and then brought to a fab shop.

- Another solution could be used to keep the pump from falling off. I'm surprised the pump PTO opening doesn't have the lock or ball detent to securely hold it onto the male PTO.

-

August 9, 2011 at 4:41 pm #32893

I went with the violet!

Pump don't seem to be working…here's what i did:

Filled gear box.

Filled tank with 6 gal fluid.

Filled hose with about 1/2 qt. fluid before i hooked to pump.fig. it would help to prime it.

Checked PTO to make sure it was working before i put pump on PTO.

Set PTO to 540

Left outlet hose open,with bucket under it.

Let tractor run between 900 and 1500 RPMs for a min…no fluid coming out,only a few drops,guess from where i primed the inlet hose .

Hooked the hose up and tried it again..nothing only a few air bubbles spitting fluid, coming from the cover vent holes on the tank.

Is there anything i missed??????????

I won't start it again “til I hear from you..

Thought I'd be digging up the garden by now…..hope it's not a faulty pump

Appreciate all your advice

Ben………….

-

August 9, 2011 at 5:15 pm #32894

Hi Ben,

Simply reverse the hoses on the pump. The gearbox changes the pump rotation, so maybe on your tractor the PTO actually turns the same as the engine. Not so on others.

Nice job on the brackets.

Account deleted.

-

August 9, 2011 at 6:57 pm #32896

No need for adapters Ben, just swap the bolted flanges.

That copper piece won't last 30 seconds when you start workin it. Use a 1″ steel EMT coupling instead (for the very short term).

Account deleted.

-

August 9, 2011 at 8:11 pm #32898

Yes,i was thinking about that..like swapping them from the other end of hose..Right??I fig. that out while watching Nancy Grace.Breaking News…Think Before You Post!! Ha!

Thanks Bob!

Ben…

-

August 9, 2011 at 11:36 pm #32902

The flanged hose connections, from side to side on the pump.

Account deleted.

-

August 10, 2011 at 6:42 am #32905

Good thing i checked the form this morning before i worked on the pump!!

Will i ever learn?

I'll switch connections on the PUMP..

So simple,hope old age is not doing that to me

Thank You Bob

Have a Great Day!

-

August 11, 2011 at 12:58 pm #32921

Hi Ben ,

it seems you have the same problem than me with your lw6 (inverted hoses) see my last post LW6 Backhoe problem, I have just received a Prince pump this morning to replace the blown factory pump ,I hope it will work …

-

August 11, 2011 at 2:28 pm #32922

I looked at some old post by Bob Rooks,he didn't have anything good to say about the LW6 he owned at one time..wish i had to read this form before i bought my LW6….

Anyway the brackets i made up didn't work the pump must have moved on the PTO and came out about 2 inches.scrapped that!….so i chained it to the tractor,started it up let it run for awhile..perfect when i moved the controls on BH it worked fine ..When i checked the pump fluid was leaking,looked like from gearbox because the around the pump was dry.Checked the BH tank only 1/2 full i lost about 2 gal…..

It's back to square 1 again…Figured i was all set up ready to go……The chain works fine,damage must be from the brackets i installed……

Good Luck with yours Streetrod!

Maybe seals in pump?? Help me again Please!!

The fluid seemed to be coming from the gearbox,but it's full,BH tank is down a few gal.

Ben

-

August 11, 2011 at 3:00 pm #32923

Streetrod,

Be sure to check your shaft rotation. The pump will have arrows on it.

Account deleted.

-

August 11, 2011 at 3:03 pm #32924

From streetrods post……………after one minute the pump shaft seal blows and a massive fluid leak under the pump gearbox

Guess that's my problem now!

-

August 11, 2011 at 3:08 pm #32925

Ben,

The gearbox should only be about 1/2 full, not to the top.

The hydraulic system will take about 2 to 3 gallons to fill all of the cylinders, hoses, and valves.

It now sounds like a blown pump shaft seal, a casualty from initially running the pump dry. Not a big job to replace. Tommy has pump kits. Can you tell if the oil thats leaking is hydraulic or gear oil?

In looking at your pics again I see that there is quite an offset. Probably should have gusseted those offsets.

Account deleted.

-

August 11, 2011 at 3:17 pm #32926

Dear Ben ,

Your pump made the same than mines….Horrible experience I have 2 units here and I cannot sell them because nothing works , if you remove pump from gearbox you will see the shaft seal outside the “C” clip causing hydraulic fluid passing thru the gearbox ,the first time I has just replaced the seal in place to make some test on BH controls ,only few drops leaks from gearbox when operating stabilizers but when I tried to move the digging joysticks the seal blows again ,I has received a PRINCE pump this morning as recommended by some CTOA users and I will install it shortly ,but I think the problem are into the joysticks and I don`t want to blow a $600 pump for fun

I have pics of the failed seal but I don`t know how to join them to that post

-

August 11, 2011 at 3:54 pm #32927

Hi Ben and Bob

Bob you just said the seal failure are caused by a pump running without oil , right .

Ben`s problem are inverted hoses like my 2 new BH causing running pump few seconds without oil ( time to realise pump not sucking oil )

Do you think if I install a new factory pump on the gearbox ,with the hoses at the right place ,she will not blow

I bought a Prince pump $650 for the BH I want to keep for me

but I have 2 units one for me and one for sale ,and I can get a CBN pump locally for $325 for the BH I want to sell (faster than possible ,cheaper than possible)

sorry again for my bad english

Thanks

Stephan (streetrod)

-

August 11, 2011 at 4:22 pm #32928

Streetrod wrote:

“Do you think if I install a new factory pump on the gearbox ,with the hoses at the right place ,she will not blow?”

Well it shouldn't. Depends if there are any restrictions that woud cause deadheading. If the pump is mounted on a Chinese tractor's splined shaft, with a gearbox, the suction side will be on the right, as viewed from the rear. The same as if it was directly mounted with the four bolts for the tang drive.

Account deleted.

-

August 11, 2011 at 4:44 pm #32929

Bob wrote:

The gearbox should only be about 1/2 full, not to the top.

The hydraulic system will take about 2 to 3 gallons to fill all of the cylinders, hoses, and valves.

It now sounds like a blown pump shaft seal, a casualty from initially running the pump dry. Not a big job to replace. Tommy has pump kits. Can you tell if the oil thats leaking is hydraulic or gear oil?

In looking at your pics again I see that there is quite an offset. Probably should have gusseted those offsets.

Bob,it's hydraulic fluid,there was to much came out to be gear oil and the gear box is still full,but it looked like it was coming from between the gear box and shaft not gear box and pump…….Do i take it apart?what should i look for?

Thanks,i must be getting to be a real pain

Ben…………..

-

August 11, 2011 at 4:47 pm #32930

Thanks bob for fast reply,

I made the same than Ben ,I have disconnected the small hose who runs to the controls to see the oil flow ,pto at idle for less than one minute ,nothing drips .. inverted hoses mounts and pump shoots oil , but maybe the pump has been already damaged and cannot hold pressure enough to move big cylinders , don`t know

the stabilizers movement dont makes pump seal blow ,the release valve must not be the problem?

I cannot spend more money just to try ,it looks like a financial nightmare

Stephan

-

August 11, 2011 at 4:58 pm #32931

My pumps working fine,but when i move the joystick it blows out fluid around the gear box.

Did you buy BH direct from china? How much freight?

Good Luck

Ben..

-

August 11, 2011 at 5:41 pm #32932

Ben,

Apparently the pump seal has blown into the gearbox, thus filling the gearbox and blowing that seal also. Seems that there should be a vent hole on top of the gearbox and the oil would have come out of there first. Hmm.

You can probably get a new gearbox shaft seal at NAPA or a commercial shop. Don't know offhand who carries those parts domestically. In any event, you need a pump seal kit, maybe the gearbox seal will be OK once you take care of the pump.

Streetrod,

It sounds like your pressure relief valve has debris in it, holding it open. Disassemble and clean it. Make sure to count the turns on the adjusting screw so you get it back close to the same pressure.

Account deleted.

-

August 11, 2011 at 6:09 pm #32934

Thanks Bob,

Stupid question,but do i have to take pump and gearbox apart?

-

August 11, 2011 at 8:15 pm #32936

You will have to unbolt the pump from the gearbox (four cap screws), then disassemble the pump (four long bolts w/ nuts). You will only need to take off the front of the pump to replace the shaft seal, but if you get the kit disassemble the whole pump. Make witness marks on the ends and body so you will get it back together exactly.

Account deleted.

-

August 11, 2011 at 8:21 pm #32937

Thanks Bob,

Have a good one!

Ben

-

August 11, 2011 at 8:36 pm #32939

Forgot to mention: Keep everything CLEAN! But you already knew that.

Account deleted.

-

August 12, 2011 at 7:22 am #32942

Hi ben and Bob ,

I will try to disassemble the relief valve this morning ,but I have no idea how it works ,I got a new CBN pump yesterday $325 plus tax ,and I`m afraid to put it on the gearbox

I will also get some fittings to fit the PRINCE pump on the BH I will keep for me ,

you has already mentioned Prince pumps are better than CBN ,Is it a good idea to make tests with this one after cleaning the release valve

Thanks for your patience

Stephan

-

August 12, 2011 at 10:06 am #32944

Streetrod wrote:

“you has already mentioned Prince pumps are better than CBN ,Is it a good idea to make tests with this one after cleaning the release valve”

Not sure what you mean.

Account deleted.

-

August 12, 2011 at 1:45 pm #32949

Streetrod i'm in the same boat as you!

Bob,took pump apart ..did't blow the seal out.but looks like damaged spring..few nicks on seal,don't know if i done that taking it out….few pics

Have a Look..

Cheers

Ben

-

August 12, 2011 at 4:23 pm #32950

Hi Ben ,

I just came back from Hydraulic shop with new hoses and fittings for Prince Pump ,I have to go to work and I will install everything tomorrow ,BH # 1 problem supposed to be solved

but I have news about our CBN pump ,I get my blow pump to that shop and the guy told me you should not invert hoses “BUT” we dissasemble the pump and he shows me how invert gears into the pump to get it right ,the guy are convicted THE PROBLEM IS CHINESE PUT ON GEARBOX PUMPS WITH WRONG ROTATION ,It is right…. first ,this guy is a génius and he give us the solution ,

As stated precedently I got a new CBN ( I can get one for you too if you want ) and I will not take any chance and this guy will invert gears on that pump Monday morning and testing in the afternoon ,

I has tested the gearbox on tractor and pump hole turns counterclock our pumps are clockwise

It seems the boat will be on the shore shortly !

Stephan

-

August 12, 2011 at 4:56 pm #32951

Thanks Stephan,

My tractor PTO shaft turns clockwise,it a Kioti tractor much like Kubota.

My LW6 BH is supposed to be under warranty for 12 mo.,i emailed and phoned them 3-4 times,but no response from them…I got it on ebay so i can always leave neg. feedback if they won't replace it!

Did your pump blow oil out from the gearbox?

You Said:

I has tested the gearbox on tractor and pump hole turns counterclock our pumps are clockwise

My pto turns clock wise!

Anxious to hear how yours works out!!

Good Luck

Ben

Pump CBN-E310 CBN-E310Hydraulic Gear Pump Your Price: $193.69Jinmaparts.com

1850 Godfrey Drive

Waupaca, WI 54981

-

August 12, 2011 at 5:18 pm #32952

I will post results as soon as possible ,It`s possible a mistake has been made at the BH manufacture to get the same problem at both end of Canada ,do you has ordered your BH on E-bay ,a BC company who sells motors to put on bicycles ? If yes they don`t have any parts

I have ordered the 2 BH direcly from China early this spring and both have the same problem than yours ..Bizarre

Stephan

-

August 12, 2011 at 9:33 pm #32953

Stephan,

Your hydraulic guy only flipped the pump body around end to end (which is a little more advanced), he didn't “invert” any gears (they will only work in one direction). That way the slightly larger port is on the suction side. That won't make much difference anyway because you will never be using that pump at capacity. You will find that you will only be able to operate the hoe at around 1,400 r/m max. Any operation at higher r/m's will result in barely controllable functions because of the poor quality of the Chinese valve stack and large ID hoses. You'll see.

Ben,

The seal must be perfect, no nicks allowed.

Account deleted.

-

August 13, 2011 at 6:50 am #32955

Your the man Bob!

The search is on for the seal. # on seal HARF 18 30 8/10 28

Enjoy your weekend!

Ben…………

Waiting on Stephan to try the pump out………

I just read

every post in this thread and came to the conclusion that #1 if i had to switch connections on the pump in the 1st place and used the chain to attach pump to PTO I'd be a happier old man now..

every post in this thread and came to the conclusion that #1 if i had to switch connections on the pump in the 1st place and used the chain to attach pump to PTO I'd be a happier old man now..

You all tried to help,i just didn't understand it very well…Live and Learn!

-

August 13, 2011 at 11:25 am #32957

Hi Ben

The BH # 1 with Prince pump works perfectly ,without cleaning anything ( I don`t know how clean a release valve ) but anyway it works ,It`s like Christmas for a 5 years kid

by now BH # 2 ,Ben we are in front of the same problem with our CBN pump ,I really regrets the purchase of that replacement pump last wednesday and I have no idea how much time consuming it will take to get results ,so if you have no guarantee from your supplier ,get a Prince Pump HC PTO 7A on e-bay and go to your local hydraulic shop to modify hour hoses ends (SAE) to fit on the pump ,

I took mine from this seller mooney99_1976_1 $395 plus $85.65 USPS shipping

Stephan

-

August 13, 2011 at 11:45 am #32958

That's great!

Found it..

New Prince Manufacturing PTO Gear Pump. Part number HC-PTO-7A. 7gpm output at 540rpm. Rated to 2000psi. Female 1 3/8-6 tooth shaft. SAE #16 side inlet and SAE #12 side outlet. Will this fit ok on my PTO shaft..same fit as the CBN-3??Let me know someone….I will order it…very good price for sure…The Prince pump here cost 650.00 plus 13% tAX..

Never heard back from supplier,3 days now..emails phone calls etc.

When i was buying, it was very fast replys….Oh Well…

I'll check ebay out again!

Have a nice weekend……….

Cheers

Ben….

Your in Quebec? we've been fighting for years over the hydro from Churchill Falls…

Hook some of that up to my PTO..HA!!

Hook some of that up to my PTO..HA!!

-

August 13, 2011 at 1:22 pm #32959Is this pump ok for my 3054xs 30hp Kioti?New Prince Manufacturing PTO Gear Pump. Part number HC-PTO-7A. 7gpm output at 540rpm. Rated to 2000psi. Female 1 3/8-6 tooth shaft. SAE #16 side inlet and SAE #12 side outlet. Will this fit ok on my PTO shaft..same fit as the CBN-3??Let me know someone….I will order it…very good price for sure…

$395 plus $85.65 USPS shipping

-

August 13, 2011 at 6:52 pm #32968

It will fit on your tractor for sure ,my PTO turn clockwise like yours ,

When you will receive your Prince pump it`s very easy to fit , you will get fittings with your pump but I have not used them ,

I went to Motion Canada Hydraulic supply I give you parts numbers

you have to get the 2 pump hoses they will cut them at the pump end to install SAE fittings

I bought 2 elbow fittings

00375 f 07954 04251583

6801-10-12-nwo-fg elbow $12.72

00028 f 64328 00316735

6801-12-16-nwo-fg elbow $15.71

and two hoses ends to be install on your own hoses

00375 f 25153 00278761

6ge-10 fjx fitting $10.40

00375 f 07954 04251583

8g-12fjx bulk $12.72

Hope it will help you

Stephan

-

August 13, 2011 at 6:54 pm #32969

Hio Ben ,

the prince pump have arrows for rotation ( clockwise ) and marks IN and OUT

Stephan

-

August 13, 2011 at 7:31 pm #32970

Stephan,did you ever get the pump seal for you CBN 310 pump..you bought a new CBN pump…

For the Prince pump I thought all you needed was 2 adapters from the LW6 hose to new pump?????

You got it set up so you should know what it takes to do it…

Thanks for the information on the parts i'm going to need,Quess it will take a few weeks for the Prince pump to arrive from the US…I bought it today!

When you put it to work,let me know how it's working//

Thanks Again

Ben……….

If we learn from our mistakes we'll be experts in no time….Ha! Ha!

-

August 13, 2011 at 8:35 pm #32971

I think will purchase a prince pump for the other BH and sell the CBN on ebay to save time consuming …..

Stephan

-

August 14, 2011 at 1:04 am #32973

Good choice Ben.

When you get your new pump make sure to check the rotation arrows. Since your PTO shaft turns clockwise, the suction side will be on the left. Good luck.

Yes, it will fit on your shaft.

Account deleted.

-

August 14, 2011 at 8:00 pm #32980

This will greatly simplify the Prince pump installation. I recommend it, it saves a lot of engineering time. Prince Torque Bar Kit.

Account deleted.

-

August 14, 2011 at 9:02 pm #32981

Do i need all the above parts suggested by Stephan to hook up to Prince pump to LW6 BH….??

I want to pick up what i need before the pump arrives….

Yes,for sure the Prince Torque kit!

Thanks Very Much Bob,

Ben……..

-

August 14, 2011 at 10:19 pm #32982

If I knew how to interpret the part numbers better I could advise, but basically what you will need is:

1) One #16 (1″) SAE ORB X 3/4″ (#12) Male JIC, 90° elbow.

2) One female 3/4″ JIC hose end swivel X 3/4″ single wire crimp.

3) One #12 (3/4″) SAE ORB X 1/2″ (#8) Male JIC, 90° elbow.

4) One female 1/2″ JIC hose end swivel X 1/2″ double wire crimp.

You will need to take the hoses to a hydraulic shop to be crimped.

Account deleted.

-

August 15, 2011 at 8:33 am #32960

You will need to take the hoses to a hydraulic shop to be crimped.

You mean the 2 hoses that are on the BH now. The one from the tank and one to hydraulics??

-

August 15, 2011 at 10:47 pm #32983

Ben wrote:

You mean the 2 hoses that are on the BH now. The one from the tank and one to hydraulics??

Got this from another site…………..

The first lesson we made, was that the PTO gearbox is the worst part of the whole system. It caused the first hydraulic pump CBN-E310 to leak through the gearbox

With the new Prince pump, not only with the problems of attaching it to the Chinese fittings, I also needed to increase the size of the suction line hose, pressure hose to the valve block, as well as the return hoses. You won't be using this pump anywhere near capacity. Suction hose from the BH reservoir is a nominal 3/4″ ID, discharge hose to valve stack is a nominal 1/2″ ID.

My recommendations therefore are to stay with the CBN-E310 pump, but use GREASE in the gearbox. NOOOOO! How are the upper bearings going to be lubricated?

That is a post from someone very inexperienced, and it is their personal opinion. I had no problem connecting up the hoses to my Prince pump, in fact I even use quick connects because I leave the pump on all the time. See pic.

Account deleted.

-

August 15, 2011 at 11:19 pm #32987

Bob,your a saint to put up with me!

The more forms i read the more confused i get,anyway the new Prince pump should be here next week and i'm sure i'll have more questions then.

Had email from the company i bought the BH from and they said MAYBE they would replace the pump…I have to call them tomorrow.

Have a good Week!

Ben…………

-

August 16, 2011 at 7:42 am #32988

I admire the patience and persistence from all of you. At the same time, it seems your supplier, who made money on this, has provided you no support at all? Who sold you this? Maybe there's a lesson learned to not buy from this company?

-

August 16, 2011 at 10:10 am #32989

Received email today..

I'm very sorry to hear about these recent issues you've run into with the pump. I do apologize for the delayed reply back as I was out of the office last week. I did try to reach you earlier however wasn't able to get a hold of you and left a message. Would you please kindly call me at your earliest convenience? I can be reached at 285-8688. I hope to speak with you soon so I can clarify the problem with the pump and have the replacement taken care of for you.

Called again this morning and left message,waiting for call back

I'll give them the benefit of the doubt for now and hope he returns my call and takes care of the problem.

Cheers

Ben………..

-

August 17, 2011 at 8:01 am #32994

Hi ,I went to the Hydraulic shop yesterday ,and they have disassembled the CBN pump to change direction as promised ,again they told me chinese have made a mistake about pump rotation ,they also stated all the pumps who blows seals are not junk ,just change gear roration ,(seems simple for spécialists ),replace a new seal ,and you got a new pump without any problem ,but they are cheap and can be never compared to a Prince pump ,the Cadillac of pumps

I project to make tests tomorrow morning and give you the results ,maybe it could help somebody to not spend money like Ben and me

Stephan

-

August 17, 2011 at 8:45 am #32995

By the way guys,the supplier called me and said they would reimburse me for the cost of new pump just send the paypal invoice

I did that..waiting for the $$$$$$$$$$$$

I did that..waiting for the $$$$$$$$$$$$ Stephan,good to hear from you again.

We didn't have very good luck with our LW6 BHs ..couldn't even find a seal for the CBN pump,so i have one on order also got the Prince pump on ebay,should have it next week about the 26th they said..Maybe if i had to know what i was doing it might have worked out better!

Anxious to see how you get it set up!

Good Luck with it

Ben

-

August 17, 2011 at 5:58 pm #33004

Ben wrote:

By the way guys,the supplier called me and said they would reimburse me for the cost of new pump just send the paypal invoice

I did that..waiting for the $$$$$$$$$$$$

I did that..waiting for the $$$$$$$$$$$$ They are going to pay for your new Prince pump? Very cool.

Account deleted.

-

August 17, 2011 at 6:46 pm #33005

Hope so,have to wait and see..looks promising …responding to my emails anyway.

This one tonight:

Hi Ben,

Thanks very much for sending this information over to me. I've already made a note of this in our system and if you would please let me know how much the duties come out to when you receive the shipment, that would be much appreciated. From our phone conversation, it definitely seems that the original PTO pump included with the backhoe is the culprit and cause for the leaking.

Please do stay in touch and let me know once the replacement arrives and I'll be glad to have you reimbursed.

Warmest regards,

-

August 17, 2011 at 7:00 pm #33006

I have not yet tested the CBN modifications now ,but if it works ,I will sell the pump and gearbox to get back money ,hope to forget this nightmare ,if i reorder BH in future I will never ask for pumps and buy Prince pumps for every BH

-

August 17, 2011 at 7:09 pm #33007

Hi Ben ,

ask for the full refund for the Prince pump from your seller

the shipping from China are nearby $ 200 for a CBN pump priced at $40

and they dont like to ship little parts too moch time consuming

Hope it will help you

Stephan

-

August 17, 2011 at 9:37 pm #33009

The shipping takes the good out of it,especially shipping to Canada..40.00 for a 31

0 pump………..

Here's a deal in a LW6 BH on ebay,,,,,free shipping to US 2675.00

http://cgi.ebay.com/NEW-3-POIN…..3077wt_861

Don't think i'd buy another China BH………..

-

August 17, 2011 at 11:40 pm #33010

I believe those guys are just importers, not actual dealers like Tommy and Ronald that have a brick and mortar service and parts departments. I will always recommend staying away from importers because most often you get dropped like a hot potato once the final payment is made, and that is when the Bill of Lading is signed and your tractor or machine is placed on a ship. Then it's between you and the shipping company and/or forwarder.

Account deleted.

-

August 18, 2011 at 8:55 am #33012

Yep,your right there Bob!Once when they get your cash there's little or no support after….IF i get the refund on pump it might change my mind a little bit,just a little tho.

Have a good Day!

Ben

-

August 18, 2011 at 5:08 pm #33014

Another day more $$$$ and time down the drain

Received new seal today, same old problem…left and right stabilizers

seemed to work ok. That was it,as soon as i moved the other joy sticks the fluid poured from between the pump and gear box…3rd seal same thing…..

The pump and gearbox was hooked up the correct way,with chain and didn't move from the pto spline…felt proud of myself for a few minuets!!!

I'm going to take a break from that piece of crap until the Prince pump arrives and give you guys a break to..lol

Thanks everyone for helping this Old Fart out

Cheers

Ben………………

-

August 18, 2011 at 7:13 pm #33015

Ben/Stephan,

I'm sure you've asked yourself on many occassions why the pump shaft seal is not holding up!? Why is there so much pressure at the pump that causes the pump shaft seal to release!? Once Stephan installed the Prince pump why didn't he encounter any issues!? You've tried reversing the hoses, modifying the pump and you've tried various ways to mount pump gearbox to the PTO…what can be causing this problem!? Can it be that there is some serious design issues with the pump gearbox setup!? Is there a piece miissing on the gearbox to keep pressure on the pump shaft seal!? How can this be determined without spending a whole lot of money!? All to say that you'll probably never find out and that can be quite frustrating…but don't lose any sleep over it!

It looks like the Prince pump is the direction to go to solve the chinese bachoe pump gearbox issue. Thanks for posting your issue and I can tell you that once I start having problems with my backhoe pump gearbox, I'll definitely immediately switch over to the Prince pump.

-

August 18, 2011 at 8:08 pm #33016

I've been watching this with great interest and admire the patience of those involved. Ironically, my own self-import frame mounted Jinma hoe is arriving next week and I hope to not repeat this nightmare. A Jinma dealer friend, Bolton Power, is coming over with his own pressure relief valve/gage setting gizmo so that we start off on the right foot. He's been advising me for a long time that the China hoes are quite powerful and he usually sets the relief pressure on the low side, especially for my “284”.

My pump is made to fit the tractor via the blockoff plate above the PTO but I won't take any chances.

Again, I admire the patience and teamwork I've seen on this thread.

-

August 18, 2011 at 8:20 pm #33017

I have been selling Jinma Tractors for years now, In 2002 I ordered a container of these backhoes, it was one of the biggest nightmares I ever had, in order to keep the customers happy I stripped 3 or 4 units for parts, and had alot of problems with the others,I said I would never buy another one and haven't.While there are bargains on Chinese equipment, I think you will find that you will find 20-unhappy Chinese backhoe owners compared to a Happy one.By the time you do all the mods to them to upgrade them you could have bought a quality Korean made backhoe that are very powerfull and smooth as glass to operate.

If you are fortunate enough to get a good chinese backhoe, and you have a hydraulic cylinder leak good luck on finding the correct kits to rebuild it.

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

August 18, 2011 at 9:12 pm #33018

Don't want to steal the thread.

Tommy's right, especially from his deep experience and we're seeing that now in this thread.

I'm not the average case in that I spend around 8 wks per year in China and bought my hoe factory direct at a price where I'm willing to deal with problems.

Back to original thread…..

-

August 18, 2011 at 9:36 pm #33019

Appreciate all your comments,should have done more research before the sale not after. for the sake of another few dollars i could have had something like this:

TomCat Korean backhoe BH650 Backhoe $ 4,500.00(didn't see this before) even if it cost extra 1000.00 or more for freight would be well worth it., I'm sure this thread will help others decide on the best bang for the buck and not make the mistake i did.

There's lot's of old post here and other forms that should make the buyer beware…

before you buy!!

before you buy!!Prince pump might help….we'll see next week when it arrives..

Can't thank you guys enough for trying to walk me through this.

Have a nice Weekend!

Ben………

PS…….Is there anyone out there that got good results from theses china made BH???

-

August 18, 2011 at 10:54 pm #33021

Smalljobs wrote:

“My pump is made to fit the tractor via the blockoff plate above the PTO but I won't take any chances.”

FYI, it's the same CBN pump that Streetrod and Ben have. I suspect that there is too much clearance between the gears and the ends. It only takes a few thousandths to break the shear strength of the oil seal (not the lip seal).

Account deleted.

-

August 18, 2011 at 11:00 pm #33022

Is there anyone out there that got good results from theses china made BH???

Yes

I need to qualify with the fact that this is my first tractor (284) and the JW03 backhoe was installed. I had never used a backhoe before. I did have some problems with it primarily the pressure relief valve for some time till I got it figured out. The controls were not very precise. It was powerful enough for what I needed. I never had any problems with the CBN pump. In fact I liked that it was pretty directly tied to the engine RPM and did not need to mess with the PTO speed shift lever. I would not trade the learning that I got from that and the work that got done with that backhoe.

I now have a Ansung BH660 (similar to Tommy's Tomcat). The difference is like night and day. I can use two different controls at the same time. I can move the bucket in inch increments if I want and can now be comfortable using it next to buildings, etc. I can push dirt sideways. Obviously the quality is much higher and of course it cost more.

RonJ

ronjin

-

August 18, 2011 at 11:07 pm #33023

Ben wrote:

“Is there anyone out there that got good results from theses china made BH??? “

There are at least four happy campers in this forum, at least two of which switched to the Prince pump. (I'm not included cuz I have a Korean LiTW hoe now.)

Account deleted.

-

August 18, 2011 at 11:14 pm #33024

Tommy@Affordable wrote:

“If you are fortunate enough to get a good chinese backhoe, and you have a hydraulic cylinder leak good luck on finding the correct kits to rebuild it.”

That's not true. I bought at least two kits from you and three from Phillip at Circle-G before I got the correct kit. Believe it or not, they do exist.

Account deleted.

-

August 19, 2011 at 4:56 am #33025

I have a 3pt LW-7, bought in 2006. I have read enough so that I would purchase a different BH were I doing things again. That being said, I have been doing OK.

I assembled the thing from a crate, with no directions but little difficulty, a couple functions I got backward but swapping hose connections fixed those. My CBN pump blew a seal (http://www.youtube.com/watch?v…..UabDrfjATY) immediately, went the Bob Rooks advised Prince pump route.

The hoe does not operate smoothly, although I have learned during use and it's better now. And operating at slower RPM's helps quite a bit as well.

I don't have the caliche issues some have, I'm in an old glacial lake area in sand. I use it for stumps (slowly preparing for a future orchard) and have plans for a ground source heat pump install. So the soil doesn't give me issues, but popping roots is still a pretty good work out.

Also, my tractor has not broken in half, despite dire warnings from posts elsewhere. I know folks probably cringe at that picture, but don't worry, my step-son was holdin' muh beer.

I know things could change tomorrow, but so far I'm happy. I have an eye on the Prince Wolverine 6 spool monoblock valves, which currently sell for about $450 on ebay. But that would also involve dealing with the metric ORFS issues (which may get better someday). But for now, I won't fix things that ain't broke.

If I depended on this for a living, I never would have chosen the LW-7, or Jinma for that matter. I can put up with any inconvenience, I can handle things as they go wrong.

I did upgrade my ZL-30 FEL valve to a Brand LV22 valve, the Chinese valve was OK, but I wanted float and am looking to add a spool via the PB circuit for a grapple.

-

August 19, 2011 at 7:43 am #33026

Bob Rooks said:

Tommy@Affordable wrote:

“If you are fortunate enough to get a good chinese backhoe, and you have a hydraulic cylinder leak good luck on finding the correct kits to rebuild it.”

That's not true. I bought at least two kits from you and three from Phillip at Circle-G before I got the correct kit. Believe it or not, they do exist.

Bob, if you were happy why don't you still have yours ??Why did you switch to a Korean backhoe ? I have ordered rebuild kits 8-10 times, I have at least 250 kits that do not fit any of the LW-06,07 or the HW06,07 backhoes.

I'm not saying there are not some happy owners of these backhoes, because there is. However most have spent additional money for either a Prince pump upgrade, fittings or JIC adaptors,Valve replacements,hose upgrades,ect.If you put that additional money spend on top of the original cost you are alot closer to the cost of Korean made backhoe, without having to work on it.

I bought at least two kits from you and three from Phillip at Circle-G before I got the correct kit. Believe it or not, they do exist.

Before you got the right kit ?, so your saying you had to go thru 5 kits to get the correct one. ? Well I guess the do exist at some point.

The point is that I personally have seen and talked to alot of customers that purchased these backhoes,almost all have said it was less expensive but would not do it again.

Thats why this forum is here for owners to talk about there equipment, and as a dealer I'm going to express my opinon about them too,

Each owner or potential owners has to make there own decision on if to purchase or not,but it's also the dealers job to advise them on problems,parts problems,operation problems,ect. I rest my case

Tommy

Affordable Tractor Sales

“Your Jinma Parts Superstore”

-

August 19, 2011 at 8:23 am #33027

Some GOOD news from Quebec Canada !

PROBLEM SOLVED I have just finish testing the CBN pump who have gears inverted by my Hydraulic shop ,AND IT WORKS ! YAHOOOOOOOOO!

Don`t ask me how but it takes 5 minutes to do

The pumps shipped with BH have wrong rotation ,I think we will see this issue again and again these BH seems very popular ,

Hope my efforts will help CTOA users

Ben ,i Will make you a confidence ,you will certainly appreciate the Prince pump ,I have both and definitely I will sell the one with CBN pump ,

another good news your CBN are not junk ,put a new shaft seal and ask a professional to change direction and you got a perfect package you can sell locally ,to refund you a little money ,

I will do that with my 2 failed CBN

Thanks to all supporters, specially Bob

Stephan ,

-

August 19, 2011 at 8:55 am #33028

Good News from Newfoundland…….It's warm and the sun is shinning for a change………..Happy for you!

Quick question Stephan…what's the # on the seal you installed?????

If the pump has the wrong rotation,how can it pump fluid ?

I opened the outlet hose and it pumped fluid into a container,but blows fluid out between the GB and pump when i hook up the hose and use the controls on BH

Lot's of input here………..THANKS everyone!

By the way Stephan,do you have the New Prince pump installed yet?

-

August 19, 2011 at 9:13 am #33029

Hi Ben ,I has not ordered any seal yet but i will need 2 ,

I has purchased locally a new complete cbn pump for one of my 2 BH and a Prince pump for the other (I will keep for me)

Now the hoses are at the right place on the cbn ,bigger hole on pump for sucking and small one for pressure ,no back pressure causing seal blowing ,simply an error has been made at the Chinese BH manufacture or at the pump manufacture ,

Stephan

-

August 19, 2011 at 9:24 am #33030

Thanks for fast reply. Sure hope you don't have any more problems when you start to work your BH………

Take Care and Good Luck

Ben………….

-

August 19, 2011 at 9:32 am #33031

StephanHi Ben,

If you want to use your BH before receiving Prince pump ,I think every hydraulic spécialist can make the gear rotation change whith eyes closed … , d`ont try to invert gears by yourself ,also if your seal are not too damaged it will handle oil because the back pressure do not exist when gears are in the right direction ,if you live near an hydraulic shop it worth the effort ,

-

August 19, 2011 at 9:48 am #33032

Hi ,again

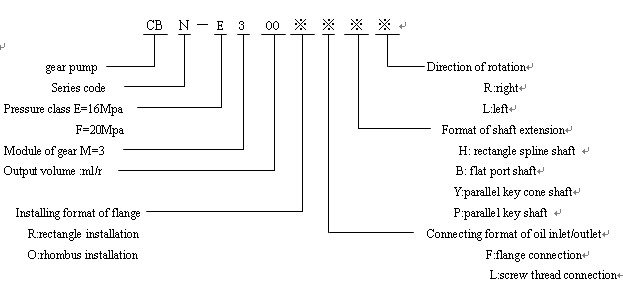

I found something about CBN pumps on the web ,these pumps are available with different rotations ,maybe just a mistake from the guy who order pumps have caused all our problems,

I was happy to see the rotation can be changed without problems ,the tech told me this kind of pump are almost the same to an italian made pump he sells (don`t remember the trademark )

Model:CBN—E310 Rate of flow:20(m3/h) Pressure:16(Mpa) Material:cast aluminium Rotate speed:2000 Efficiency:90%

With its simple structure, small size, lightweight, safe operation, and convenient maintenance,it is widely used in hydraulic system of agricultural machinery, engineering machinery, light industry machinery, railway machinery and mine machinery.

Stephan

-

August 19, 2011 at 12:03 pm #33033

Hi Ya Stephen,

I've read 100s of post and information on the pump and BH never did come across what you mentioned ….maybe your right on!

The nearest hydraulic shop to me is over 200 km away so if i go there in the next few days i will check it out.I couldn't find anything on line with instructions on how to put the pump back together,but all i did was replace the seal didn't take the pump or gearbox apart.

We're not in the same boat anymore…..i fell overboard…Ha!

Take Care

Ben………..

Big Thank You Bob,Bert,Rich,Ron J,,Small Jobs,Tommy,Stephan,Len from GA. Biggerten and all the help from other members ..

-

August 24, 2011 at 5:25 pm #33064

That's great that the dealer refunded you with the price of the new pump! Let us know the final verdict once you've got everything up and running!

-

August 24, 2011 at 6:07 pm #33065

Hi Bert,

Happy to get the refund for sure!

Just wanted to be 100% sure i can use same hoses,only changing ends going into

From CBN 310 to Prince pump…..

From CBN 310 to Prince pump….. If not i'll get new hose.

If not i'll get new hose.Thanks

-

August 24, 2011 at 6:30 pm #33066

Ben,

If you look at post #77 from Streetrod (Stephan) and post #88 from Bob Rooks mentions only to change the ends of your present hose to fit the new Prince pump.

-

August 24, 2011 at 6:48 pm #33067

Yep..3-4 times…

Now i'm 100% sure! Let you all know when it's up and running.

Thanks Bert……….

-

August 25, 2011 at 1:19 am #33070

Remember to use elbows otherwise you'll have hoses sticking out. May as well do it neatly while your at it.

Account deleted.

-

August 25, 2011 at 4:04 pm #33071

Hi Ben ,

happy for you to get full refund of your new Prince pump

let us know how is your BH with the Prince ,

The shop have not used fittings included with Prince pump they sold me 2 elbows and 2 crimping ends nothing more ,

Good luck and happy digging !

Stephan

-

August 25, 2011 at 4:05 pm #33072

Hi Ben ,

happy for you to get full refund of your new Prince pump

let us know how is your BH with the Prince ,

The shop have not used fittings included with Prince pump they sold me 2 elbows and 2 crimping ends nothing more ,

Good luck and happy digging !

Stephan

-

August 25, 2011 at 8:49 pm #33077

Ben wrote:

“,,that pump is a heavy one!!”

Yeah, I'd say bulletproof.

That's exactly why mine stays on, and why I have quick connects on it.

Me? Mad at you?

Account deleted.

-

August 25, 2011 at 8:56 pm #33078

Account deleted.

-

August 25, 2011 at 9:39 pm #33080

Finally pump installed..so far so good

Trying to post some pics of my first dig,but get this message' DSC08861.JPG' cannot be queued for upload as the size exceeds the maximum limit of 524288 bytes: had to lower Res in camera ……..

Big THANK YOU to all who had the patience to put up with me..

THANK YOU

THANK YOU

THANK YOU

I DIG THIS FORM……….Pics Soon……….

Cheers!

Ben……………………………..

Pushed it a bit much knocking over the trees……………….

-

August 26, 2011 at 11:50 am #33085

That's great news Ben! Take a video and post it on youtube and then add the youtube link to your next post.

Enjoy your new toy!

-

August 26, 2011 at 12:02 pm #33086

OK, Bert i'll try that video later when i get used to it!

It took awhile fooling around with that 310 pump,but seems to be ok now with the new one.

Thanks for helping out!

Ben………..

-

August 26, 2011 at 12:33 pm #33087

Ben,

What is the engine rpm you use that provides you with the best results for operating your backhoe with the new Prince pump? With my old pump gearbox setup it is around 1500 rpm.

-

August 26, 2011 at 1:43 pm #33088

Hey Bert,

1000 rpm so far it had very good power at that. I have to get the 3 pt. hitch more secure maybe brackets made up before i really push it to far.

Feel a lot better about it now then i did a few weeks ago,but i still think it be might be worth extra $$$$$$$$$$$ for the Korean BH ,

Saw this on ebay 2795.00..LW7 i think.

Cheers Ben

HYDRAULIC THUMB INCLUDED!

FREE SHIPPING!!!

-

August 26, 2011 at 3:05 pm #33089

Hi Ben ,

My BH works very well with the Prince pump but another problem occurs ,( this time on my 2011 Jinma 254 tractor )

When the BH or another implement are on the 3 point ,a leak comes from the backplate below the small handle to adjust speed of the 3 point

I have tightened the 2 upper 21 mm bolts but the lower ones are in a very bad place

impossible to use any tool ,I will try to fix this before using the BH again

Stephan

-

August 26, 2011 at 5:11 pm #33090

Ben wrote:

Feel a lot better about it now then i did a few weeks ago,but i still think it be might be worth extra $$$$$$$$$$$ for the Korean BH ,

Saw this on ebay 2795.00..LW7 i think.

That is a LiTW BH7600, just like mine. LiTW is the Korean manufacturer, and they have Swiss valves with the power beyond ports. That is one helluva deal if you can get it for $2,800.00. I paid $4,200.00 for mine with an extra bucket and a mechanical thumb, and I was getting a good deal at that.

Noticed something in your pic of the Prince pump: the piece of metal that you used for the reaction bar is too light. Appears to be about 3/16″ – 1/4″. If you are going to use flat stock, it should be 1/2″ minimum, or 2″ x 2″ x 1/4″ angle. The bar that comes with the kit is 3/4″ x 3/4″. Also , the S-hook you are using will open right up before you pop the relief valve – recommend using a cold shut chain link instead.

Don't want you to get hurt and wreck all of the good work you've put into it so far.

Now that you have it up and running (congratulations!), consider mounting a return line filter as a next step.

Looking good!

Account deleted.

-

August 27, 2011 at 1:12 am #33092

Ben wrote:

“The flat stock is 3/8 they cut it at the welding shop,but it's to long hits of the 3pt. hitch arm..when i rev it up to 1500-2000 rpms it hits the arm and makes a weird sound…”

WHOA! Stop right there! If your PTO turns clockwise the reaction bar must be on the right side of the pump, pulling the chain tight when the pump is running. If your PTO turns counter-clockwise the reaction bar must be on the left side of the pump, pulling the chain tight when the pump is running. The chain should be as short as possible and still allow the pump to float without coming off the shaft. One way to test this is to physically try to pull the pump off, without the tractor running of course.

Account deleted.

-

August 27, 2011 at 5:42 pm #33094

Done! Everything's fine!Not perfect,but fine for now!

Have a great weekend everyone..

Thanks Bob

Ben

-

August 28, 2011 at 10:42 am #33095

Sorry, guess I misunderstood.

Enjoy!

Enjoy!

Account deleted.

-

August 28, 2011 at 1:14 pm #33096

My wife don't understand me either,especially after spending the last 3 weeks in the barn with my BH…Ha! After 47 years she should know me by now

BH running very smooth,put 2nd chain with enough slack for pump to float.

Wouldn't want to dig out a foundation for a house,but for small jobs around the property it's not bad..

Take Care..Hurricane wasn't as bad as expected..

Cheers

Ben

-

May 8, 2014 at 2:30 pm #36940

Just a note of appreciation for this three year old thread, as I'm undertaking the replacement of my hydraulic pump, on the Yucahai Dozer with the '6 hoe.

rannit dry, i duz b'leeve.

-

October 23, 2014 at 10:55 am #37298

Good Luck with yours Dave!

I appreciated all the help and advice from Bob Rooks and all the guys who took the time to walk me through install of the LW6 BH.

I never did get much digging force from the LW6 even tho I switched the china pump for a Prince pump .

I sold tractor and BH …Purchased a Kubota BX25D with BH a few months ago,really surprised about the power it has for digging.Great for doing landscaping etc.

Thanks again to everyone who helped!!

-

-

AuthorPosts

- You must be logged in to reply to this topic.