Forum › Forums › Tractor Troubleshooting › Posible hyd. pump failure

- This topic has 18 replies, 6 voices, and was last updated 12 years, 9 months ago by

Carl Darnell.

-

AuthorPosts

-

-

June 3, 2012 at 3:32 pm #30585

Well, it finally happened. Over last summer and especially the winter the FEL and 3pt hitch started slowing down. Over winter and this spring it was getting worse. This morning I was going to dig some dirt for a neighbor and the bucket and 3pt hitch didn’t really want to lift. I headed to the dirt and dropped the bucket and plowed into the hill and then the bucket would not lift at all. I backed out and went to high idle and the bucket barely moved but I finally got it high enough to get home. The steering was a little jerky like it was getting low on fluid but the level was ok.

I drained the reservoir and pulled the seat and suction filter. The filter is clean and there was no metal in the drained oil. I refilled it with new oil and it still won’t lift the bucket or 3pt hitch. I guess it’s time for a new hyd. pump.

Before I order a new pump is there any ideas on maybe the diverter valve or something?

The tractor is a 2000 NT254 with about 800 hours on it.

-

June 4, 2012 at 11:05 am #34687

Hydraulic pumps usually don't go out that quickly, unless there is a catastrophic failure, like deadheading or drive coupling failure.

I don't know a lot about wheeled tractor hydraulic circuitry but I would start checking valves first.

Account deleted.

-

June 5, 2012 at 2:00 am #34691

Carl,

Do you have a pressure gauge on your system or can you hook one up?

RonJ

ronjin

-

June 5, 2012 at 9:26 am #34692

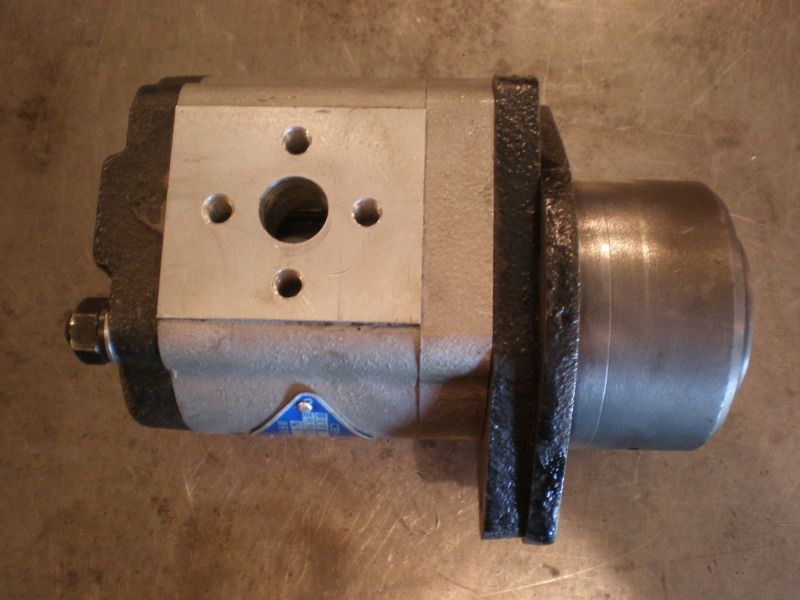

I talked to Jerry at Affordable Tractor and he said it sounds like the pump has worn out. I asked about the diverter vavle and he said from what I was describing it doesn't sound like that's a problem. I decided to order a new pump. Thinking about it more I am remembering the system has been slowing down over a few years. Anyway, I'll replace the pump and see what happens. I guess I need to find a port to put a pressure gauge on to monitor the pressure over time.

Unlike some that seek advise I will post the results one way or the other.

-

June 5, 2012 at 10:33 am #34695

Carl wrote:

“Unlike some that seek advise I will post the results one way or the other. “

Thanks Carl, I really appreciate that.

If your pump performance has been degrading over a years time then I agree, it's pump time.

Account deleted.

-

June 6, 2012 at 10:48 am #34698

Bob, it aggravates me to no end when we discuss a failure and give advise and then never hear from the complaintant. Common courtesy requires me to post the results of the problem. My hope is the pump fixes it. Thinking about it the FEL has been getting weaker over the years.

-

June 8, 2012 at 10:31 am #34704

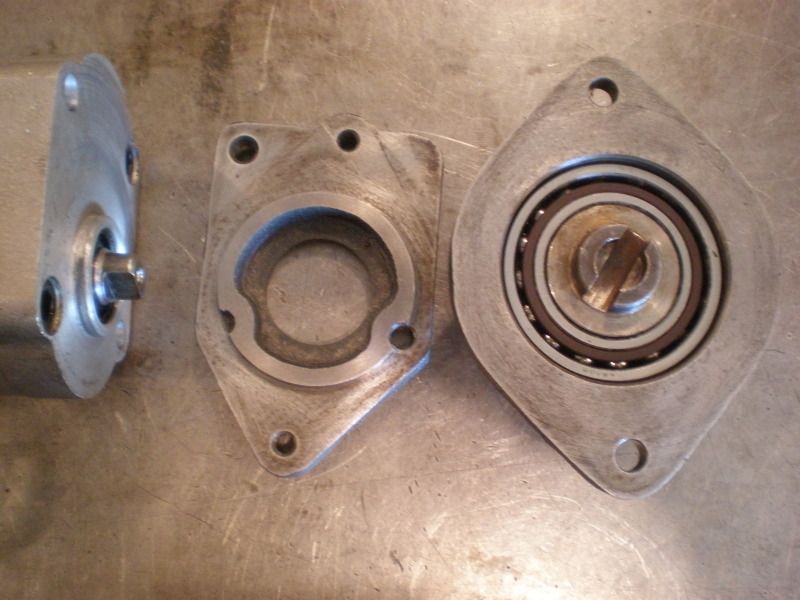

Ok, I got the pump in and pulled the old one and the outside edges of the tang was badly worn and it may have been slipping in the drive slot. The drive slot doesn’t have a lot of wear but it does have a hole in the center so the pump tang is only driven on the outside edges. My question is can I pull the drive assembly out of the front cover without affecting the timing of the cam to crank? I intend to weld the drive slot up and machine a slot across it so it has full contact.

I know this has been discussed years ago and I wonder if there is an update drive unit that I can buy. Does anyone remember the many threads about this several years ago?

-

June 8, 2012 at 3:05 pm #34705

Here’s my solution to the problem of the tang not getting full engagement. I did some measuring and if I leave out the pump mounting gasket and the adapter plate gasket the tang will go in far enough to get good engagement and it doesn’t bottom out against the drive component. I will use a thin coat of RTV in place of the two gaskets. Jerry is sending me a mounting gasket for the gear drive assembly so I don’t have to make it.

The drive gear shaft is hardened and if I weld it up I will have to grind the slot out rather than cutting it out. I hate it when you have fix a manufacturers screw up. Why the hell did they machine a hole in the middle of the slot? It serves no useful purpose and is detrimental to the job the slots supposed to do.

-

June 8, 2012 at 3:06 pm #34706

A updated ? We have replacement pump drivers ?

Tommy

Affordable Tractor Sales

” Your Jinma Parts Superstore”

-

June 8, 2012 at 3:08 pm #34707

That hole did not come from the factory ? All of our drivers have just a Slot No Hole ?

Check this link, this is for a assembly but I have just the drivers too

Tommy

Affordable Tractor Sales

” Your Jinma Parts Superstore”

-

June 8, 2012 at 5:26 pm #34708

Tommy, that hole is in a factory part that was never off my tractor. A friend bought it new and nothing has been done to the hydraulic pump until now. At some point there must have been a part revision because my part is original to the engine.

Also, I do remember some threads about this on the old site. Some owners were complaining about the tang getting worn off on the outer edges and they had to replace the drive unit and the pump. I remember that because I was concerned mine might fail and was tempted to pull the pump and check it out. I decided to run it until it fails and apparently the pump failed first but I haven't torn the pump down yet to see what has happened. The only other thing I guess is the diverter valve.

-

June 9, 2012 at 12:32 am #34709

It would seem to me that 90% of the load is on the outside of the tang anyway, so the hole in the middle shouldn't cause a significant different in ability to transmit power. Some, yes. A lot, no. Look at the multi-drive type screws that have combination Philips.slotted heads. They hold a straight blade screw driver just as well as a full slot, sometimes better.

-

June 9, 2012 at 7:11 pm #34710

Rich, did you look at the enlarged photo of the tang on the pump in one of the above posts? If so you would see that much of one side was worn away. I will tear the pump apart this weekend to inspect it but the drive tang is badly damaged from having the hole in the center of the drive slot. It's a poor design that was obviously changed at a later date. Probably after complaints from dealers and customers.

I do remember this was a problem when I first joined the site in 2005.

-

June 9, 2012 at 7:47 pm #34713

I just took the pump apart and I don't see any signs of failure. The only issue is the worn tang. I will use the new pump and see what happens but I am suspecting there are other issues than the pump.

-

June 10, 2012 at 1:58 am #34717

Carl,

Yes, I saw the tang damage and that appears to be more an issue of inadequate engagement depth than one of radial loading. I think the scheme you mentioned for obtaining greater engagement depth for the tang will do the trick and solve the issue.

As far as eyeball visible signs of pump failure, I doubt you could determine anything much less than a catastrophic sort of failure mode – the clearances in a hydraulic pump are so tight you need very fine measuring instruments to determine wear that would make the difference between good performance and nearly no performance at all. Vacuum pumps are even worse to try to visually diagnose.

Best of luck with it!

-

June 10, 2012 at 2:23 pm #34720

Yes, had they made the part right in the first place without the drill hole in the center there would be no tang wear.

My silly putty had gotten to hard to use so I drove my motorbike to town and got some new silly putty. I put a piece in the groove and assembled the pump, adapter plate and drive unit and took it apart and removed and measured the putty and it's about .070″ thick so there is plenty of end clearance so it's not going to bottom out.

When the gasket comes in I will put it all together and give it a test run. I'm not really convinced the pump has worn out but anyway the only remaining issue is the diverter valve. Has anyone had one them apart? I'll call Jerry Monday and pick his mind too. I'm starting to think a sliding valve in the diverter may be stuck.

Put your thinking caps on fellows. The site used to be real active with lots of posts.

-

June 10, 2012 at 2:47 pm #34721

Mine has the twin pumps, no diverter valve. I have a similar job this week, putting an oil pump in the wife's car. There are specs in the manual to check clearances, but at 190,000 miles I'm not putting the old one back in anyway. Is there an easy way to bypass the diverter?

-

June 10, 2012 at 8:46 pm #34725

Not really, to many lines. I talked to Ron today and he told me a lot of things to look at and ideas. When I get the gasket I will put the pump on and start doing the tests he suggested.

-

June 16, 2012 at 4:42 pm #34770

Here's the rest of the story. I talked to Ron at Ranch Hand for a long time one Sunday about this issue. He said I probably couldn't see anything wrong with the pump even it it's not pumping and he is right. He said he has had a lot of experience with the hydraulic systems and told me exactly what to do and look for. He said the bodies will expand over time and loose their ability to make pressure.

I ordered a drive shaft for the assembly and some seals for the priority valve. Then I pressed the drive assembly apart and removed the bearings from the shaft. The little bearing came off easy and the big bearing outer race came off leaving the inner race on the shaft and my balls fell in the bucket

, well the ball bearings anyway. Ok, inspection of the bearing shows it's a one side thrust bearing because the helical gear teeth push the drive towards the big bearing. Well crap, so I called Ronald again and had him send some bearings.

, well the ball bearings anyway. Ok, inspection of the bearing shows it's a one side thrust bearing because the helical gear teeth push the drive towards the big bearing. Well crap, so I called Ronald again and had him send some bearings. As to the drive shaft I am sending it to Ron for his museum of strange parts and as proof of a stupid design.

I just got the bearings today and since I need the tractor and the Jeep engine is still giving me fits I decided to work on the tractor. I put everything back together with a few expletives tossed in to assist the assembly of everything. I filled the reservoir and started it up and now it lifts as fast as it ever did.

I measured everything and mine has the short drive shaft. Without the gasket between the adapter and the adapter and the pump I have about .070″ clearance between the end of the pump shaft tang and the bottom of the drive shaft slot. That gives perfect mating of the tang and slot for maximum contact.

It's dribbling rain right now so I can't give it a real lifting test outside.

One thing I found out is the pump is self priming because the pump is below the reservoir. I had oil running all over the floor until I tied the line up high.

-

-

AuthorPosts

- You must be logged in to reply to this topic.