Forum › Forums › Bulldozer & Excavator Troubleshooting › Too cold to dig? foaming out the dip stick, Help

- This topic has 25 replies, 4 voices, and was last updated 13 years, 3 months ago by

SpringValley.

-

AuthorPosts

-

-

December 11, 2011 at 12:07 pm #30467

Hi, this is for a LW7, running a prince 7 gpm pump, fed with 1.25 inch hose, 3/4 inch outlet hose. It was 24 degrees this morning, 34 now, 10:45am, no power when I first started to dig, I let it high idle for about 45 minutes with the pump on, ran it at 1,200 RPM, I then had decent power to dig but it started to foam up and come out the dipstick and fill neck, running 32 weight, Oil is 55 degrees, tractor hydraulics work fine, I have a septic tank coming tomorrow, I need to dig. Any thoughts appreciated. It was the same temperature outside yesterday, hoe dug fine, I didnot change anything overnight, tried to dig at idle speed, was jerky almost no power, ran it up to 1,000 RPM. decent power, started foaming out the dipstick again.

-

December 11, 2011 at 1:28 pm #33886

If you have a magnetic heater stick it on the bottom of the hydraulic reservoir. It sounds like you might be getting cavitation from cold oil on the suction side. I've seen that before but not at 34°.

Account deleted.

-

December 11, 2011 at 3:44 pm #33887

Well its pretty nice out now, boom would not lift so I swapped the thumb valve hoses for the boom hoses and had the same problem. I assume this means my cylinder is bad. Any opinions welcome

PS when it foams out the dip stick I am trying to lift the boom with no success, I am essentially deadheading it (Not real long).

PSS 2,200 PSI on my gauge, filter vaccume gauge reads zero (Brand new cartridge, showed about one stone cold at 25 degrees)

-

December 11, 2011 at 4:34 pm #33888

Does everything else work ok except for the boom?

Account deleted.

-

December 11, 2011 at 5:08 pm #33889

I guess, new hoe first real dig with it. Bucket opens and closes good, dipper works fine, swing left and right is sloppy but I understand the swing cylinders are a weak point on this hoe. I never really had a chance to test the thumb, works fine, I needed the dipper and bucket hooked up to see if it would pick up a bucket of dirt, so disconnecting the thumb was my only choice. I might add, boom did come up with no dirt in it, just wold not come up with a full bucket of dirt.

-

December 11, 2011 at 7:23 pm #33877

Two possible scenarios John:

1) Boom cylinder cup seals are bad, oil is by-passing. Possible early indication of eminent failure.

2) Debris stuck in relief valve, preventing full pressure.

Account deleted.

-

December 12, 2011 at 1:14 am #33890

ronjin

-

December 12, 2011 at 6:43 am #33891

I understand I can buy new seals, Ranch Hand Supply I think, how hard and what is the procedure to replace them? Special tools helpful? I only have O-ring picks.

-

December 12, 2011 at 10:34 am #33892

Not sure if Ronald or Tommy carry kits for those cylinders anymore but you can check.

Circle-G does carry kits here.

Replacing the seals is pretty straight forward, the boom must be lowered and supported. If I remember correctly the cylinder doesn't have to be completely removed. just disconnect the rod end and remove the seal end of the cylinder and pull the rod and piston out. There are two types of cylinder seal ends used, one end screws on, the other uses snap rings. Be sure to relax all of the backhoe cylinders first, and have an oil catch pan under the boom.

Account deleted.

-

December 12, 2011 at 12:37 pm #33897

I just thought of one more test, remove the retract hose and open the extend valve and see if it bypasses oil.

My pressure is a constant 2,200 psi and I switched control valves from the thumb to boom to rule out a control valve issue, so the bypass oil test is the only thing left to test, I think, let me know, thanks all for the input.

-

December 12, 2011 at 1:51 pm #33899

I you fully extend the boom, dipper, and bucket off the ground, shut off the tractor and walk away, does the boom fall by itself?

Account deleted.

-

December 12, 2011 at 2:05 pm #33900

Bob, no, it stays up, no leak down at all.

-

December 12, 2011 at 5:06 pm #33901

OK, foaming in essence increases the volume of oil. Foaming is caused by turbulence, a natural occurrence in hydraulic systems. As a rule of thumb, the minimum reservoir capacity in gallons must equal or exceed the GPM rating of the pump. This allows for adequate time in residence to deairate the oil and allow for enough heat dissipation before continuing the cycle.

Are you using ISO AW 32 Hydraulic Oil specifically?

Is your reservoir at least 7-8 gallons?

Account deleted.

-

December 12, 2011 at 11:10 pm #33907

“Bob, no, it stays up, no leak down at all.”

Let me clarify something. If the seals are leaking by the boom isn't necessarily going to come crashing down, instead look for small slow movement, say a few inches max. until the oil in the cylinder becomes “equalized” and a hydraulic lock occurs. At that point the piston will stop moving unless a valve is actuated. maybe try that again. I apologize for not being clear.

Also, try to positively rule out any suction side air leaks.

Account deleted.

-

December 13, 2011 at 9:15 am #33909

“Also, try to positively rule out any suction side air leaks”

Recall I just replaced the factory suction hose with 1 1/4″ hose and also put in an inline filter, I could have goofed up something there, I did my best to make sure my connections were tight,

How does one diagnose suction side air leaks?

-

December 14, 2011 at 2:47 am #33911

John,

If I wanted to see if I had a suction leak, I would wrap “saran” wrap around the suction hose and clamps – then see if there was any difference in the backhoe operation.

How do you have the thumb connected into the hydraulic system?

Since you are constantly getting 2200psi on the gauge, I don’t think that there is a Priority Relief Valve problem. Next thought would be a problem with the Boom spool.

I don’t think that swapping the thumb and boom hoses would give you the testing that you needed. I would have swapped the dipper and the boom so that boom spool could get a good strong exercise.

I gather from reading through the thread that you and LenBo did the same modifications on the LW07. I suggest that you might want to check with him to compare hydraulic tank information. Let me see if I can describe why I suggest this.

Over the years in talking to other Chinese backhoe owners, it became obvious that the same model number, year, serial number, etc. did not mean that the end product was the same.

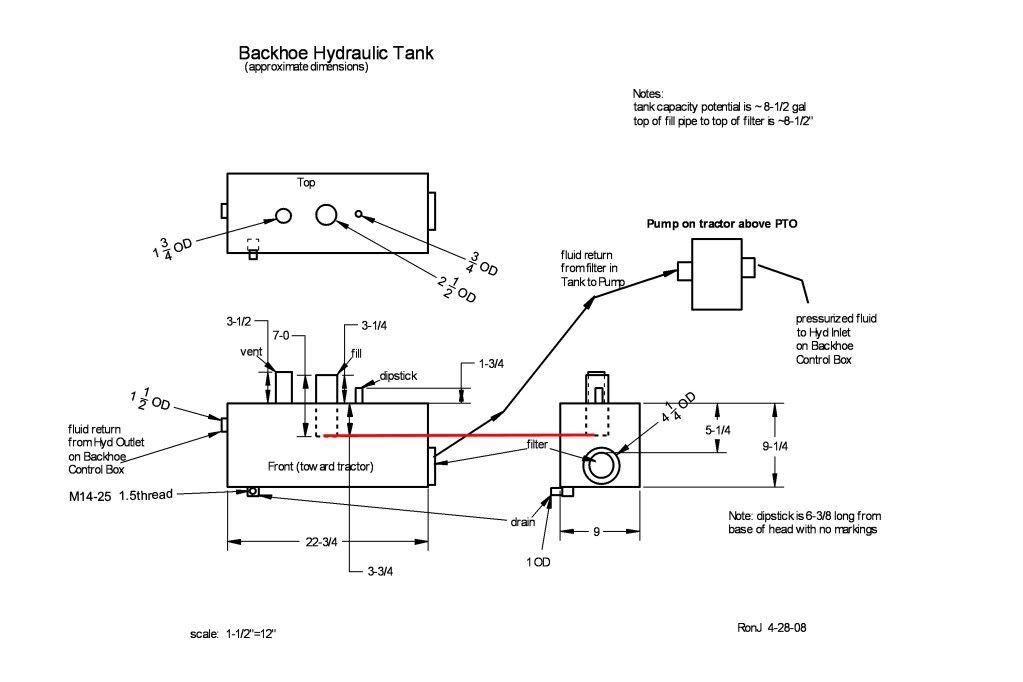

The picture below is one that I put together for myself to better understand my backhoe. The external dimensions would indicate that it will hold about 8-1/2 gallons.. Over the years in talking with other owners, it took awhile to understand a major difference in tanks. With my tank on the left top there is an outlet designed for venting. This means that I could use 8-1-2 gallons if needed.

Others did not have this vent. I have drawn a red line at the bottom of the filler pipe that reduces the useable capacity to about 5 gallons. We determined that if their tanks were filled above the bottom of that pipe, there was a large buildup of pressure at the top of the tank. Some installed a vent pipe like mine and others came up with other venting solutions. This allowed them to put more useable gallons in the tank.

RonJ

ronjin

-

December 14, 2011 at 10:52 am #33912

Ron, thanks for your comments

I like the saran wrap idea, will try it this weekend

Its a factory thumb, has a spool valve in the middle of the block, I will have to take pictures this weekend

I chose the thumb boom swap as I could reroute the thumb hoses to the boom. To test it I needed the dipper and bucket working so I could grab a bucket of dirt to test it. The boom hoses are not long enough to reroute to another cylinder. I do not have adapters to fashion an extension of the boom hoses. I am afraid to tinker the the hose fittings on the control valve block as I have read of them leaking after being disturbed.

I will compare my tank to your drawing this weekend.

I have checked with Len he most be real busy, no response.

-

December 14, 2011 at 2:57 pm #33913

John,

Have one other suggestion.

I just spent ~ 40 minutes trying to figure out how to send you a PM and don't have any more time to waste on this site (could not even find my Email info here) – so I will post here in the public forum.

Go to the TractorByNet.com site, go to the Chinese Tractor section and post your problem there. There is a member there (RonMar) who is very knowledgeable about these backhoes and will respond if he is available.

RonJ

ronjin

-

December 31, 2011 at 8:44 pm #33970

I did that, thanks Ron

Just so this is clear I am using a:

25 GPM SUCTION LINE FILTER

New ZINGA. Spin-on type element. Ports 1 1/4″ NPT.

SPECIFICATIONS

Suction Line Applications 25 Micron

25 GPM

5 PSI bypass

950 sq in filter area

5 1/3″ dia x 9 1/3″ long25gpm for a 7 gpm pump sounds fine to me

I finally got time to work on this today, I am putting two constant torque hose clamps on all hoses, the second one pinches on top on the ridge at the end of the nipples. Every place a leak may occur is getting a coat of rtv, its sloppy, I'll clean it up with a razor blade later. I have finally had five days of sun and its dry enough to drive the tractor on the dirt tomorrow so I am doing this on new years eve, Happy New Year!

I reused the O-ring on the tank outlet fitting(originally), I didnt like how it looked, I have removed it and cleaned it good with carb cleaner and am sealing it with rtv.

I am going to remove the filter and re-oil it and retighten it.

I think I am catching every place I might get air intrusion.

I used Loctite 545 on all the pipe fittings, I am not breaking them loose at this point.

If I still have a problem tomorrow I will get a fitting and remove and bypass the filter

Note- the flow is right on the filter

If I am missing something, let me know, any ideas are welcome.

-

December 31, 2011 at 8:52 pm #33971

I have pics, I don't see a “button” to be able to post them?!?…

-

December 31, 2011 at 8:53 pm #33972

Ok, first problem, without the o-ring the outlet fitting tightened up to an unusable position, so I removed the fitting, reinstalled the o-ring-I figured it should seal this time with all the rtv and tightened it up its a tad higher than the first time (I hope thats OK).

Second problem, I could not remove the filter by hand and its too big for any filter wrench I have ,I didnt want to ruin it by putting a screwdriver in it (I do have a spare though). So I am leaving that for now, will seal it with rtv around the edges in the morning.

I cleaned the tank outlet with carb cleaner sprayed onto a brush (I didn't want to get the carb cleaner in the tank)

-

December 31, 2011 at 9:13 pm #33973

(Copy & paste)

That all looks good John, but I question two things.

1) The eyebolt on the pumps reaction bar: Was that a grade 2 eyebolt or was it a hook. If it was an eyebolt it's ready to let go. (I use a forged eyebolt on mine.)

2) The hose clamps. The constant torque type that you used have little advantage over the previous worm drive clamps. The T-bolt type clamps have a tremendous advantage. But we'll see what happens tomorrow.Happy New Year :thumbsup:

Account deleted.

-

January 1, 2012 at 7:49 am #33974

-

January 1, 2012 at 7:49 am #33975

-

January 1, 2012 at 7:51 am #33976

I cant figure out how to copy and paste, this is my new Apple computer and it does not work the same as my old computer, I cant drag pics in either, oh well I have hoe work to do.

-

January 2, 2012 at 12:52 am #33978

I cant figure out how to copy and paste, this is my new Apple computer

and it does not work the same as my old computer, I cant drag pics in

either, oh well I have hoe work to do.Copy and paste is the same as windows except use the command key instead of the control key. So copy is command C and paste is command V. Not sure what you mean by drag pics in???

-

-

AuthorPosts

- You must be logged in to reply to this topic.