Forum Replies Created

-

AuthorPosts

-

Tommy, on one side of the rod is some numbers/markings, on the other side, nothing. Which side is oriented to the front, or does it matter. I know the rod and it's cap can only go one way, but does it matter which way the assembly is oriented?

As you can tell, I am questioning my recollection on how it came apart, since it was several weeks ago. Also, I'm gonna need another sump gasket cuz I can't salvage this one. Oh, I probably could, but who wants to deal with leaks after all this. You should have my card number.

Thanks so much Tommy, at least I know now and can get back to making things right. Dangit.

Hmm…I went and looked at things again, and I'm thinking what I had called a valve indent, is maybe actually a space for the fuel to be squirted. If so, then I have the pistons in 180 out. The pisser is, I'm confident the rods are oriented right, so this means I will have to separate the rods from the pistons, etc, etc, etc.

I looked at the head, and thought I was right since the valves seemed slightly closer to the exhaust side. But once I put the head in place, I noted the head is also slightly offset to the exhaust side. So I still am not sure.

Hit another stopping point. To get right to the point, I ain't certain I put the new pistons in oriented the right way, with respect to the valve indent. I thought I had made sure to assemble them the same way as the old ones, but once I set the head in place and looked it all over, I am not so sure. In the attached photo, I am at the front of the block, looking towards the back, valve indent to the left, towards the exhaust side. The engine manual talks about it, but with the chinglish, danged if i know up from down. See attached photo

Okay, I had some issues after I put the crank in and the pistons etc…..was preparing to work on gettin the timing gears and all installed, and discovered the crank etc seemed to be bound up. This was after I had done all the torque stuff and knew they were set a-right. I also knew if it wouldn'tturn over at this point, it was trouble and I had to take some backward steps and find where I made an error. My earlier pics came in handy cuz lo and behold, I had put the main caps

Okay, I had some issues after I put the crank in and the pistons etc…..was preparing to work on gettin the timing gears and all installed, and discovered the crank etc seemed to be bound up. This was after I had done all the torque stuff and knew they were set a-right. I also knew if it wouldn'tturn over at this point, it was trouble and I had to take some backward steps and find where I made an error. My earlier pics came in handy cuz lo and behold, I had put the main caps

in wrong, and the pistons/rods were also in reversed. I discovered this after I looked at my earlier photos, and noted, the arrow on the main caps were pointing AWAY from the oil pump. I had installed then with the arrow pointing towards the right side of the engine, towards the oil pump. Okay, so I pulled the mains caps off, swapped ends and re-installed them, pulled the rod-caps, pulled the pistons/swleeves and rotated them 180 degrees, and re-installed. When i was re-torquing it all down again, I made another rookie mistake but caught it. When

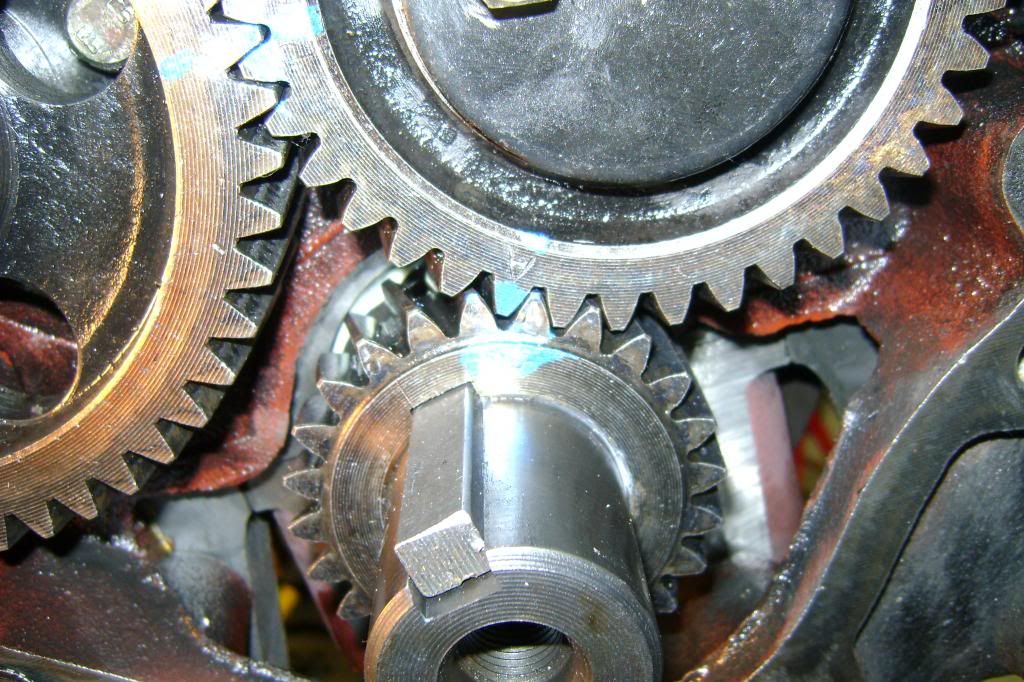

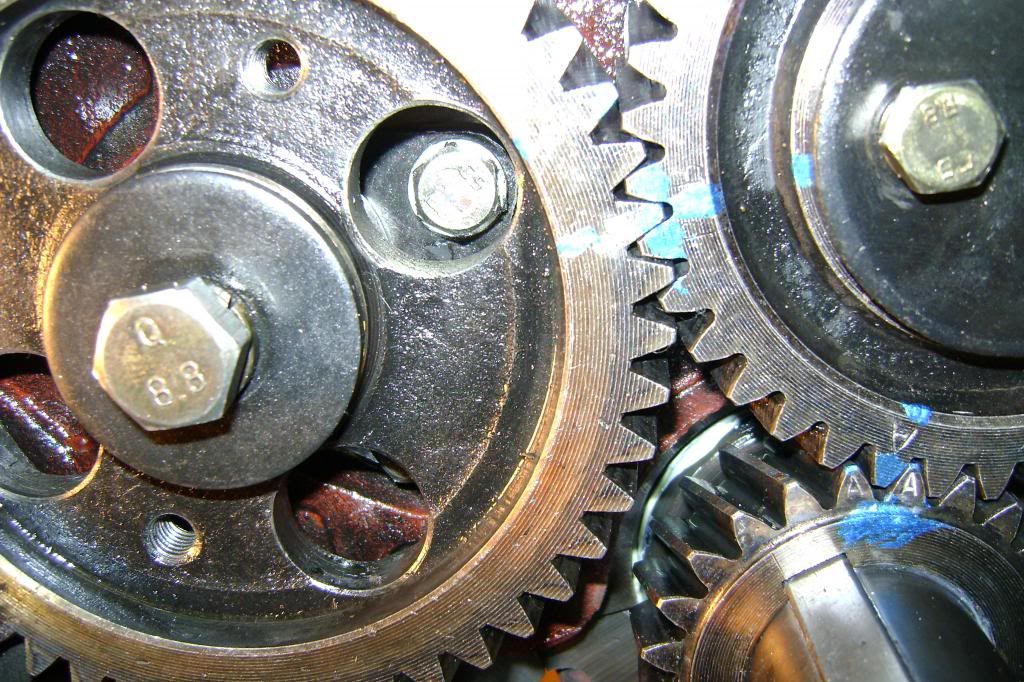

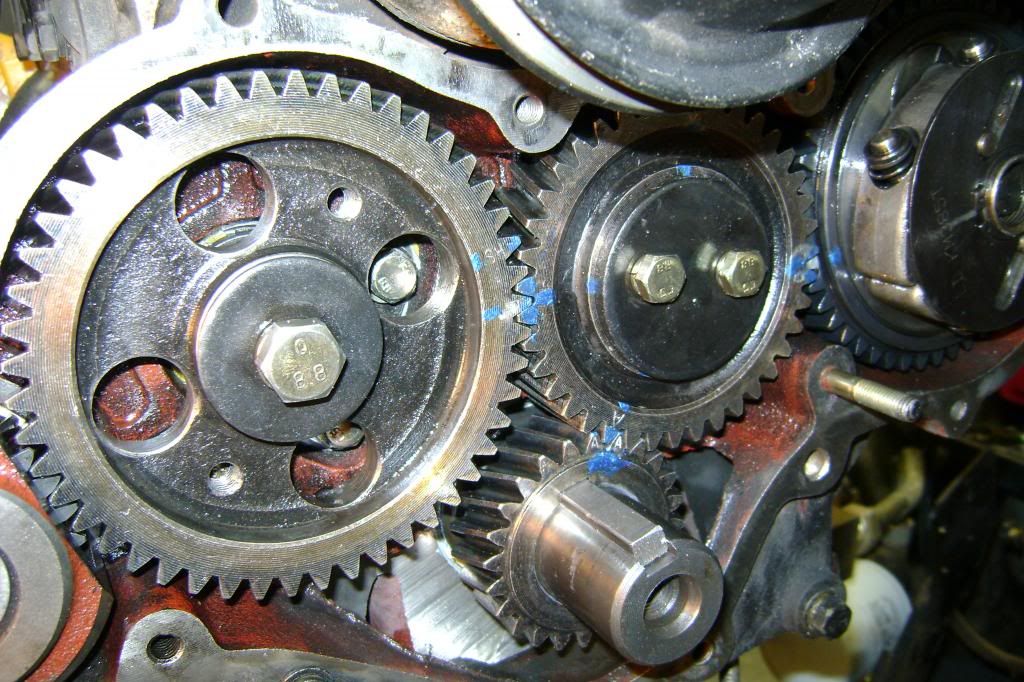

you are pulling the torque wrench for the final setting, get the bolt snug enough so you can take it to final with one complete pull till it clicks. Otherwise, you'll almost certainly get it set too tight.Anyway, after all that, and liberal applications of oil, in addition to the assembly lube, it turns over now by hand, though it's still tighter than I had expected.So anyway, on to installing the timing gears. Note, I used some of the ex's metallic blue fingernail polish to mark the gear meshpoints for easier viewing etc. Woulda used white, but she didn't leave any of that, lol. The blue worked

The crankshaft gear, has an “A” on one tooth, which corresponds to the idler gear and it's 2 teeth with “A”s . The injector pump advance gear has two teeth with “O”'s, whicj correspond with a single tooth on the idler gear, with an “O” on it. The cam gear has a tooth with a “B” on it, which corresponds to two teeth on the idler gear with “B”'s on them. This can be a little tricky to get it all to line up, but with patience, you will get it done.

The crankshaft gear, has an “A” on one tooth, which corresponds to the idler gear and it's 2 teeth with “A”s . The injector pump advance gear has two teeth with “O”'s, whicj correspond with a single tooth on the idler gear, with an “O” on it. The cam gear has a tooth with a “B” on it, which corresponds to two teeth on the idler gear with “B”'s on them. This can be a little tricky to get it all to line up, but with patience, you will get it done. Crankshaft gear meshing with idler gear

Crankshaft gear meshing with idler gear idler gear meshing with injector pump advance gear.

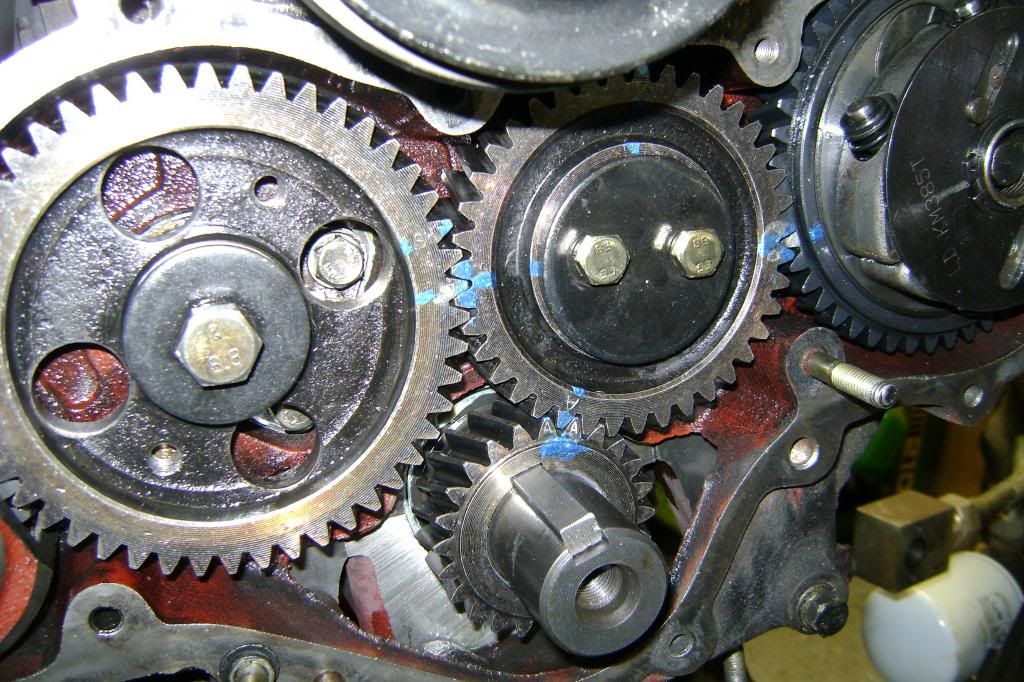

idler gear meshing with injector pump advance gear. Idler gear meshing with cam gear.

Idler gear meshing with cam gear.

View of one of the mounting bolts for the injector pump. When I was disassembling the engine, I was trying to get the timing gearcase off and couldn't see clearly how to get it to come apart. I knew the crankshaft gear hadda come off, the idler hadda come off and the camshaft gear hadda come off, and it looked like the gear for the injector pump hadda come off too. To that end, I loosened the pictured

View of one of the mounting bolts for the injector pump. When I was disassembling the engine, I was trying to get the timing gearcase off and couldn't see clearly how to get it to come apart. I knew the crankshaft gear hadda come off, the idler hadda come off and the camshaft gear hadda come off, and it looked like the gear for the injector pump hadda come off too. To that end, I loosened the pictured

nut, as well as the other two, but was unable to pull that darned gear off. Well, in looking things over more carefully, I noted one last bolt on the gearcase, and with a little judicious tapping with a brass hammer, the gearcase did begin to loosen. I knew I had screwed up by loosening those three nuts, so I looked it over carefully and could see where the pump assy had rotated from it's original setting, and I am hoping by simply resetting everythig back to where it was (fingers crossed), I can get it set close enough to get it eventually run

without doing any damage.

Nother view of the nuts. Note there is a slot which allows the pump to rotate, for setting the injector timing. I sure hope I get it put back where it originally was!

Nother view of the nuts. Note there is a slot which allows the pump to rotate, for setting the injector timing. I sure hope I get it put back where it originally was!At this point, I'm gonna take a long break and give you guys an

opportunity to ask questions, offer critiques, give advice, issue warnings, and so on. I don't want to move forward just yet, untill I have some assurance I'm not gonna hafta go back and un-do something due to a mistake.As an aside, any of you who haven't yet done so, go buy yourself a good quality head mounted LED flashlight. Dang, I did a lot of work on this project, fighting with flashlights and worklights and so on, till I remembered I had one of them lil headlights in my tool cabinet. Man, what a difference! Sure makes some of them “3-handed” jobs a lot easier if ya don't hafta hold a flashlight, or mess with adjusting a worklight all the time.

Read more: http://ctocf.proboards.com/ind…..z2HcIx2hBZ

Read more: http://ctocf.proboards.com/ind…..z2HcIEiJUS

Read

more: http://ctocf.proboards.com/ind…..z2HcFF2cVNThink that one thru. If I set torque wrench 1 (tw1) to click at 100ft/lbs, and then check it with tw2, I only know tw2 clicks at some reading at or under 100ft/lbs. Or, tw2 may click at a higher setting only because I inadvertantly, actually tightened it to a higher value. But I have no way to be sure both set to 100 ft/lbs, and ONLY 100 ft/lbs. I also don't know if tw1 and tw2 both set the same at 50 ft/lbs. Or 150 ft/lbs. I can guess and I can assume. And that may be satisfactory, depending on your application. I just prefer a bit higher degree of confidence in the accuracy of my torque setting tools. Just one more step in stacking the odds in my favor, when I am doing a job I have never done before, and have had no special training for (right parts, right tools, right books-instructions, frequently will result in a right outcome).

I could do that Dave, and I appreciate the suggestion. However I'd rather have my torque wrench calibrated to do what it's supposed to do, with an acceptable degree of accuracy. This is a long handled, ratcheting clicker type torque wrench, and I paid good money for it about 25 years ago. So it doesn't owe me anything really, and I'd rather have it checked over professionally.

Okay, UPS guy delivered the crankshaft this afternoon. So the project is back in gear. Got the mains installed and then the pistons, sleeves etc, installed and connected. Was preparing to torque things to spec, but I discovered my torque wrench had been left set at about 140 ft/lbs from the last time it was used. Annoys the crap outta me when I do something like that cuz I know better. So tomorrow, I go to town and find a torque wrench I can rent, as well as finding out where I can send mine to be re-calibrated. Oh well,

Lol, thanks Bob, I knew what it was called, but the ole memory banks just wouldn't give it out!

-

AuthorPosts