Forum Replies Created

-

AuthorPosts

-

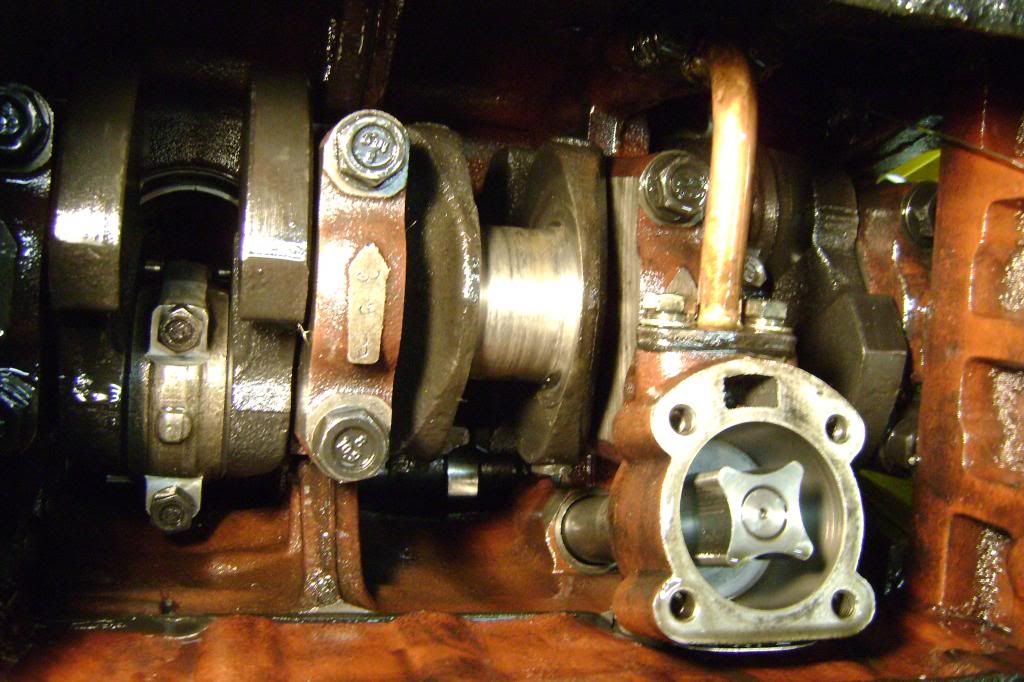

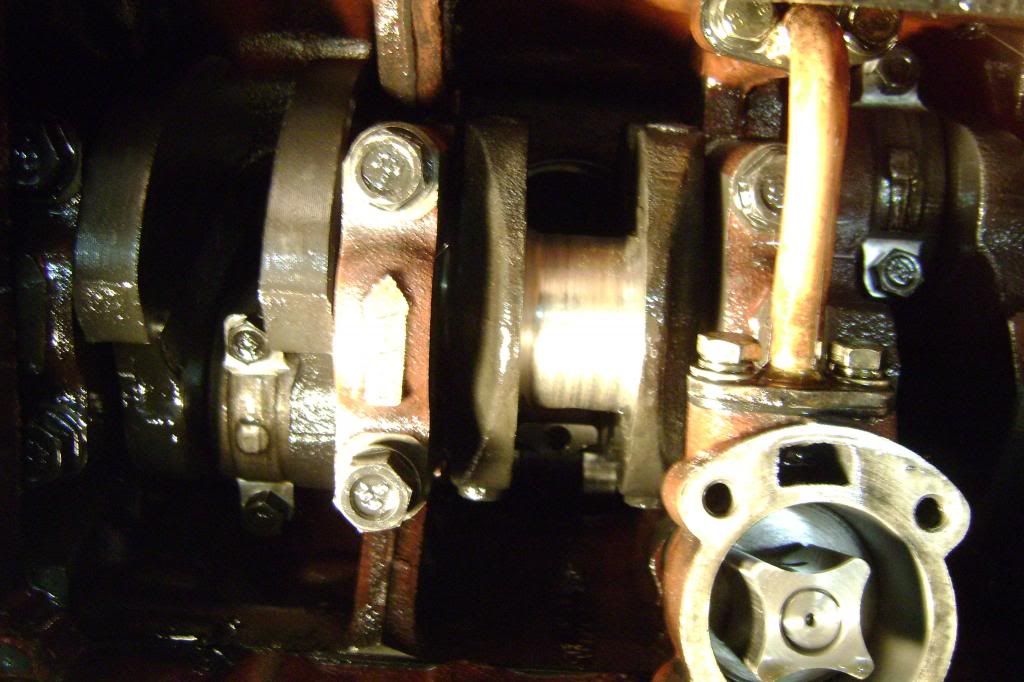

I can't say for sure which journal it was in. I was shocked to find it, and was absorbed in the process of figuring out how to get the crank out at that point (hadda pull the timing gears and gearcase off). I agree, that could certainly have been the cause of the spun bearing. I am also seeing signs of damage from what I think was either dirt in the engine, or casting sand left in the engine. I know the oil and filter was changed out at around 120 hours, and was told it had been changed out sometime prior to me buying it with 60 hours on it. Could be the air filter has been letting dirt or dust get past it, but don't yet know. Still need to get the cam pulled to see if there is damage there, as well as ensuring the bearings are aligned to allow full oil flow. I think it was okay cuz I do have oil to the valve train, but not as much as I had expected.

Much as it pains me bob, I think I'm probably going to bite the bullet and spring for new liners, pistons, rings and bearings, as well as one new rod. Oh, and a new crankshaft. I have serious doubts as to the chances of regrinding the crank, reconditioning the rod and then finding a suitable bearing to fit it. One piston and liner looks pretty good, but the other two I really don't want to re-use. I don't know yet what caused all the damage, but when I put it back together, I want to know I have done all I could reasonably do to make sure things are right. I haven't yet pulled the camshaft, but I certainly hope it will look as good out, and it seems to still in place.

The hoped for “shortblock” isn't in stock and would likely take around 8 weeks to come in, so that's probably not gonna happen. A replacement engine is over $3000, so that's not gonna happen either.

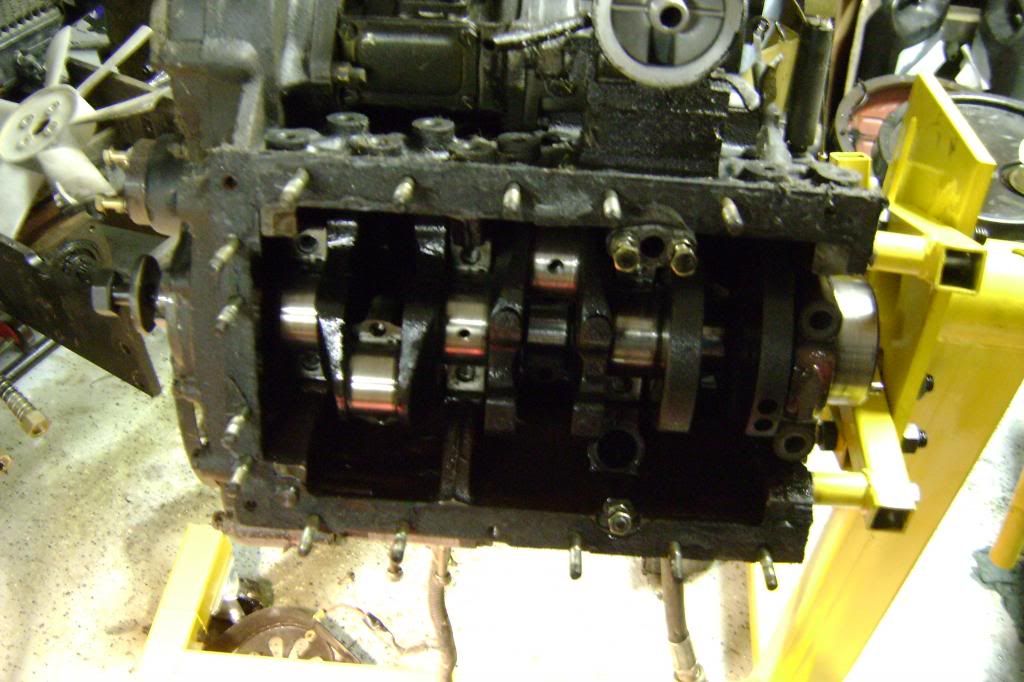

Crank pulled out.

mic'd the “bad” rod journal. Not terrible

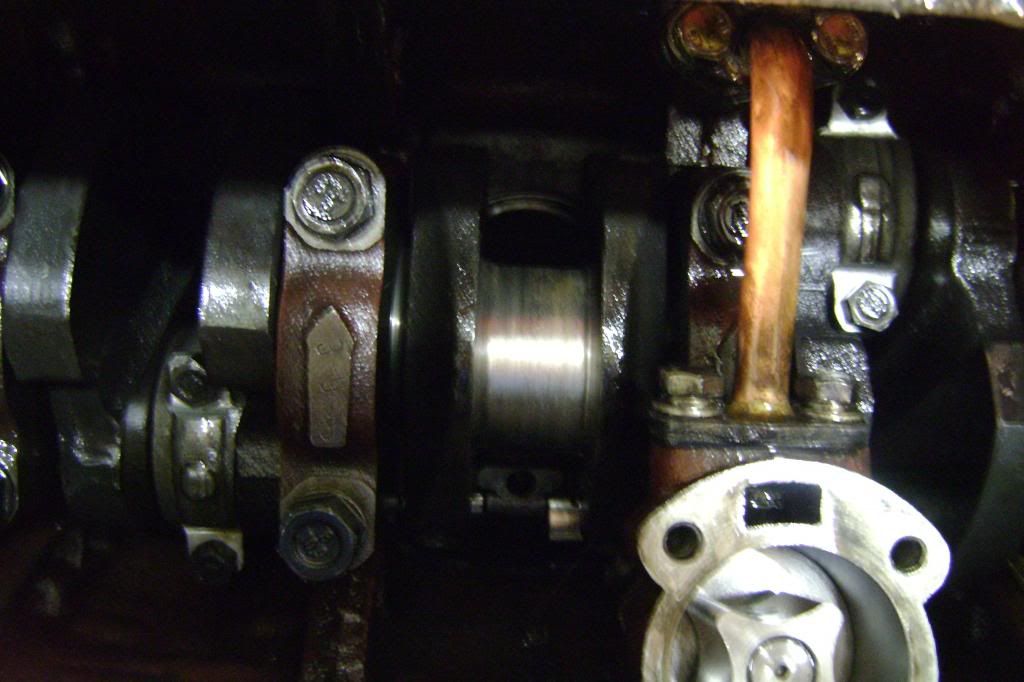

Other rod journal.

mic'd the mains, all read the same.

front piston. note the skirt scuffing.

middle piston. Again, skirt scuffing. This is the one with the spun rod bearing.

Back cylinder. Again skirt scuffing AND rust staining noted on top!

next 2 photos show the erosion inside the back sleeve.

Top deck. I see no signs of a head gasket leak. But after sitting for almost 3 years, it was way low on coolant.

Okay, so after viewing the damage, I'm asking for expert advice, from someone who isn't gonna make money on the choice. Is the piston scuffing significant enough to justify replacing the pistons? Sleeves? I know the back one has to be replaced.

As for the moisture damage, I looked and don't see any signs of head gasket leakage, but I will certainly have the head checked for flatness when I take the crank and rod in for machine work. It is possible some got in ther exhaust pipe during the time it was sitting (knew I shoulda bought and installed a rain cap when I first brought it home).

Sure wish I had a mechanic-type friend living close by, lol.

Pulled the head off. Pulled the timing gears and gearcase off. Pulled the crank. Found a plastic breadwrapper twisty tie stick in one of the oil holes of the crank. The back cylinder had a lot more soot,and the cylinder liner looked cruddy inside. Will take and post photos in the morning. Tonite I'm gonna chat with my son who is in Afghanistan.

Amazing. Back when I was over in the land of jungles and Lil nasty folks, the only time I had a chance to talk with anybody stateside, was when we went back to re-supply and once a month we might get to call on a MARS line. courtesy of Barry Goldwater.

All I know so far is, one rod bearing spun. I don't yet know why it would have yet. Will be pulling the head and valve train off tonite. Don't expect to see anything untoward there, but who knows. With that off, I will then pull the crank off and get a better look at that whole thing. Do the measurements and so on. Will post more pics once I have all that done.

Just one man's opinion; replacing the thermostant would do nothing to help warm-up unless the original was somehow defective. The hour plug in time helps starting but won't do a lot more to warm the engine. Partially or wholly blocking the radiator will speed the warm-up for sure, but don't be the guy who overheated his engine because he didn't pay close attention to what the engine temp was doing. A diesel engine doesn't generate much heat until and unless it is working. My guess is, a much longer plug-in time (say, 6 hours) would do more, but again, that's no guarantee.

As an aside, I doubt lack of proper warm-up was the cause of the spun rod bearing in my engine. The other bearings all looked okay other than evidence of bearing particles flowing thru the lube system and damaging them. But I'm no expert, and as I said, just one man's opinion.

So I called around to find an engine stand. Rental place wanted $15 a day or $45 a week. Pronto parts place in town had one on sale for $79. Use it once, sell it for $50, still money ahead. Of course, after I put it together i realized I didn't have any metric bolts to bolt the block to the engine stand, so back to town. Pronto had some, almost long enough, and he threw them in cuz I bought the engine stand there. So went back home, did a little modification so the bolts I got would be long enough.

Finished seperating the engine from the front parts, pulled the sump and the crank pully. Then marked all rod caps and bearing caps, and starte unbolting them. Got them all except the rear main cap doesn't

want to come off. It's loose but still stubborn. Time to go look at the parts book and see if there is something I may have missed. I also still have to pull the timing cover, but I want to lok that over real carefully, so I don't have a timing nightmare when I try to reassemble it.

Thanks Bob! We used to have several good machine shops in town, in conjunction with parts houses, but they've pretty much all gone by the wayside. However, there are a few good ones within 100 miles. If I can make that work out, I'll do that rather than spring for the cost of a new crank. We'll see just how much has to be taken off the one bad journal. I don't think it's too bad, but that'll be up to the machinist.

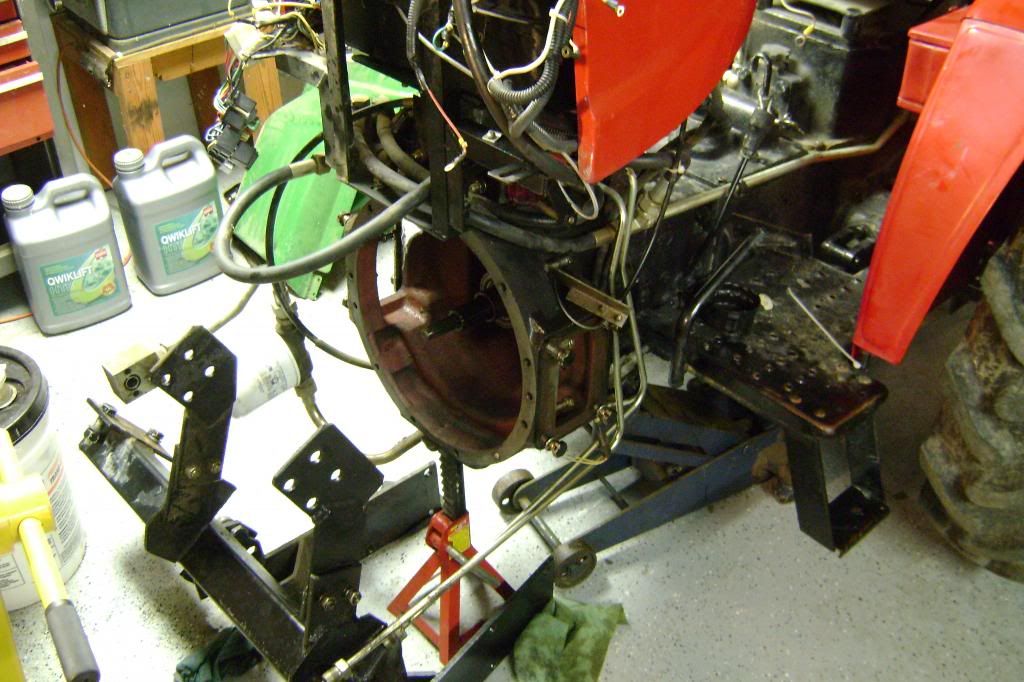

Well, I have it split, the clutch, pressure plate and flywheel off, the adapter plate off, and the tools put away for the night. Once I locate an engine stand to mount the engine to while I work it over, I'll get back at it. For now, my big floor jack is holding the transmission up, my porta-crane is holding the engine up, and I have jack stands under both just in case.

I live alone and am out in the country so if anything happened, I'm on my own. Forces me to be a bit more cautious and think things thru carefully before I jump in.

Anybody have ideas where a guy might be able to get oversize rod bearings for these tractors?

Heh, yeah, I'll agree to that. Same for the intake line from the air filter. I will probably re-engineer that set-up to make the hose shorter and find some better hose for it asd well. Once I get it all put back together.

-

AuthorPosts