Forum Replies Created

-

AuthorPosts

-

Do not try to stop with your hand – use 2×4,etc.

RonJ

ronjin

The first thing that I would do it install a pressure gauge between the pump and the FEL control valve. It is a good diagnostic tool to have regardless of what else you need to do.

It has been several years, but my recollection is that the power steering and 3pt took much less hydraulic pressure to operate than the FEL.

RonJ

ronjin

Is this about the same as your hydraulic flows?

RonJ

ronjin

Which tractor do you have? Which FEL? Do you have a hydraulic pressure gauge? How are the hydraulics 'plumbed'?

RonJ

ronjin

Give us a picture that shows where you re-installed the bolt.

RonJ

ronjin

These are the connections on my 284 that I think you are talking about.

Heavy Red wire(#1) from battery to large solenoid terminal. White wire (#2) with large connector from connector block in engine compartment to large solenoid terminal. Red wire (#11) from starter interrupt switch (under left floorboard) to small solenoid terminal.

RonJ

ronjin

Pete,

On my 284 there is a #32 yellow wire

that comes from the horn. It plugs into that white connector from

the bottom and feeds a yellow wire on the other side of the connector

that goes to the horn relay.RonJ

ronjin

John,

Have one other suggestion.

I just spent ~ 40 minutes trying to figure out how to send you a PM and don't have any more time to waste on this site (could not even find my Email info here) – so I will post here in the public forum.

Go to the TractorByNet.com site, go to the Chinese Tractor section and post your problem there. There is a member there (RonMar) who is very knowledgeable about these backhoes and will respond if he is available.

RonJ

ronjin

John,

If I wanted to see if I had a suction leak, I would wrap “saran” wrap around the suction hose and clamps – then see if there was any difference in the backhoe operation.

How do you have the thumb connected into the hydraulic system?

Since you are constantly getting 2200psi on the gauge, I don’t think that there is a Priority Relief Valve problem. Next thought would be a problem with the Boom spool.

I don’t think that swapping the thumb and boom hoses would give you the testing that you needed. I would have swapped the dipper and the boom so that boom spool could get a good strong exercise.

I gather from reading through the thread that you and LenBo did the same modifications on the LW07. I suggest that you might want to check with him to compare hydraulic tank information. Let me see if I can describe why I suggest this.

Over the years in talking to other Chinese backhoe owners, it became obvious that the same model number, year, serial number, etc. did not mean that the end product was the same.

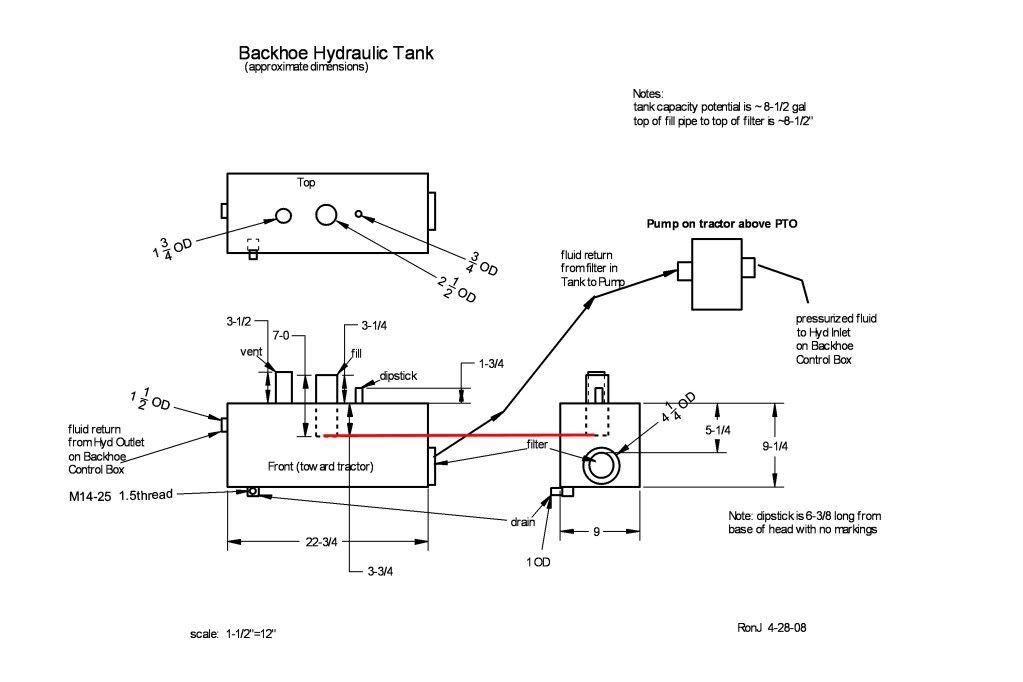

The picture below is one that I put together for myself to better understand my backhoe. The external dimensions would indicate that it will hold about 8-1/2 gallons.. Over the years in talking with other owners, it took awhile to understand a major difference in tanks. With my tank on the left top there is an outlet designed for venting. This means that I could use 8-1-2 gallons if needed.

Others did not have this vent. I have drawn a red line at the bottom of the filler pipe that reduces the useable capacity to about 5 gallons. We determined that if their tanks were filled above the bottom of that pipe, there was a large buildup of pressure at the top of the tank. Some installed a vent pipe like mine and others came up with other venting solutions. This allowed them to put more useable gallons in the tank.

RonJ

ronjin

ronjin

-

AuthorPosts