Forum Replies Created

-

AuthorPosts

-

Wills,

Sounds to me as if you may also have a starter that needs to be taken apart and cleaned.

RonJ

ronjin

They look the same to me. In my picture, the lower left inlet pipe is labeled as Hyd Inlet. Trace the hose that feeds that fitting to assure that it goes to the output side of the pump.

RonJ

ronjin

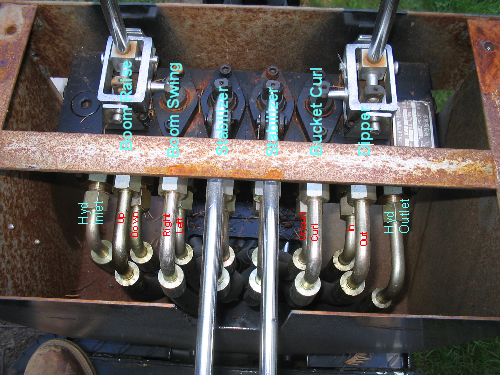

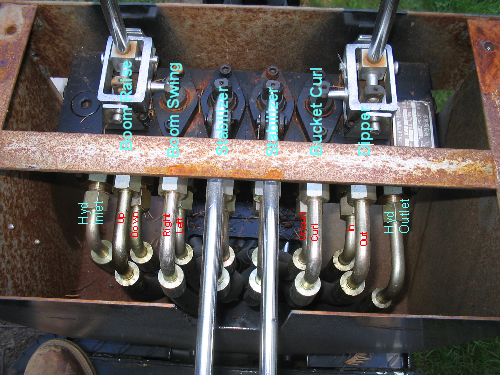

Here is what the spools look like.

RonJ

ronjin

Hymay,

Yes, I see that you have the pump that is driven off the PTO Auxiliary shaft rather than the PTO shaft. Personally I prefer that type of pump. It is directly driven by a shaft that is controlled by engine speed alone. But mainly there are only 4 bolts to mess with when connecting/disconnecting. There are no chains, etc to prevent the pump from spinning.

I would be interested in pictures or a sketch of the hydraulic holding tank since I haven’t seen one like that before.

In the meantime, let’s keep going. Here is a picture of the control valve on my JW03. Is yours the same?

RonJ

ronjin

Hymay,

Where did it dump all of this oil from?

Mine is a JW03 frame mount and I didn't realize that the 3pt mount BH looked so different.

I don't believe that the size of the tractor makes any difference. The backhoe is driven by the hydraulic pump that hooks on the PTO. If that pump is the proper size for the backhoe needs, it should be fine.

RonJ

ronjin

When you look at the left portion of the picture, the lower left line is labeled as Hyd In. The portion of the control valve that is just above that and to the left holds the Relief Valve. It has a screw plug with an allen wrench removal slot.

Here is a picture of the relief valve assy.

RonJ

ronjin

First let us see if we are talking about the same control valve.

ronj

ronjin

Clyde,

I have no idea of the weather and temperature in Nova Scotia, but if it is warm enough to have melted any ice in the engine – I would:

- Drain the engine oil crankcase and see what is in there.

- Remove Glow Plugs and Injectors.

- Tie off the compression release in an open position

- Turn the engine by hand. There is a bolt on the center of the pulley. Challenge will probably be getting a socket and long ratchet on it.

- If it turns over, stop until you get replacement oil in the engine.

Let us know the results.

RonJ

ronjin

Len10,

Here is the technique that I used to check the possible leakage on my FEL cylinders.

1. Raise the bucket about 3 feet off the ground with the bucket level with the ground.

2. Block up the bucket to hold it in that position. I used a combination of a 4×4 and a floor jack.

3. Turn off the tractor and wiggle the FEL controls to release any pressure in the lines.

4. Remove and insert plugs into all of the hoses that feed the FEL cylinders.

5. Remove the blocking from under the bucket.

6. Use a ruler to measure height from the ground to both the back and front of the bucket.

7. Leave it that way and periodically remeasure both the front and the back height of the bucket also record the times.

This takes the FEL control valve out of the picture and should give you some data points to determine whether there is leakage in the cylinders, how much and whether it is both tilt and/or lift cylinders.

If it is leaking down then isolate by plugging one cyl at a time. When they are connected to the valve the cylinders are tied together so it only takes one bad cylinder and it will leak down. RonJ

ronjin

Either NAPA2276 or FRAM CAK256 should work for you.

RonJ

ronjin

-

AuthorPosts