Forum Replies Created

-

AuthorPosts

-

What FEL do you have?

Which FEL control valve?

RonJ

ronjin

janb.

One more thought – when it is that cold, I suggest that you get the oil up to room temperature before trying to put it in that injector pump. I can't stress enough the need to fill it slowly.

RonJ

ronjin

janb,

I think that you are trying to fill it too fast. The oil has to go in very slowly or it just comes right back out. I have to use a large syringe type of device so I don't try to get too much in at one time.

RonJ

ronjin

Janb,

Can you post a picture?

If not, perhaps we can figure out your injector from the picture that I posted above.

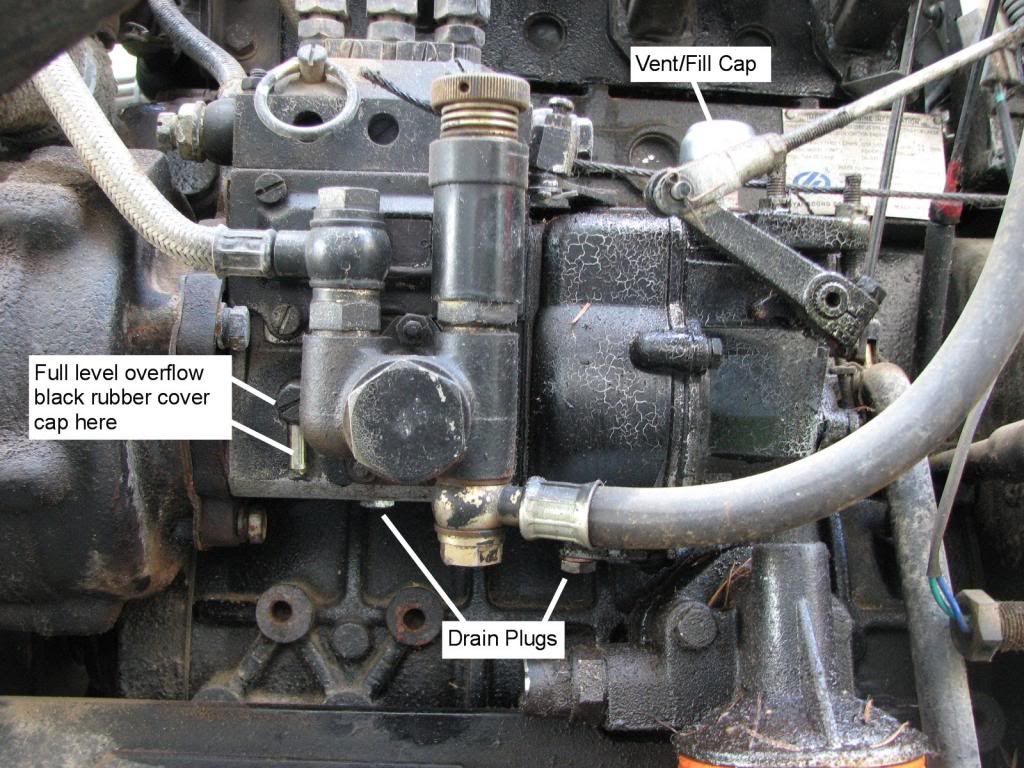

- Do you have the hole on top? (On mine it has a vent cap. On some it has a dipstick or cap.)

- Do you have the 2 drain plugs at the bottom?

I don't have a dipstick and have never missed it.

The refill process is to open the 2 bottom drain holes so the oil is drained from the internal forward and rear chambers.

Put the drain plugs back in and SLOWLY fill with oil. It will only go in slowly without overflowing.

When the oil begins to drip out of the fitting in the left of the picture, it is full. (On mine you can see a small tube just under the bolt. On some I believe that that the bolt needs to be removed to allow the oil dripping to indicate a full condition.)

Since the oil moves so slowly through the system, I then let mine sit for several hours until that dripping oil stops completely (since you do not want the system too full of oil).

RonJ

ronjin

janb,

Is this what you are talking about?

ronjin

On my 284 I use 28 in the front and 16 in the rear.

If I am doing some extra lifting, etc – I then add or reduce air to keep the proper tread profile on the ground.

RonJ

ronjin

dogdoc,

It is important to break loose those bolts before re-torquing.

Over time, heat, paint, etc will 'freeze' the bolt heads (and to different degrees). To be sure that they are all torqued correctly and equally, they should each be broken loose and retorqued. Do them one at a time so you don't disturb the head gasket.

RonJ

ronjin

I would take the rocker assy off so that when you do the re-torque you will feel sure that the bolts are all evenly done.

RonJ

ronjin

Can you tell by looking at the head or doing a rough measuring estimate?

ronjin

Follow the PTO lever to where it connects to the shaft. Thoroughly clean that area. Place the PTO lever in the up position. Using a straight edge and scribe or nail make a mark across both the lever and shaft. Move the PTO lever to the bottom position. If that scribed mark looks exactly as it did before, your problem is internal. If the scribed mark is slightly off, it is probably the pin that connects the lever to the shaft just behind your scribe mark.

RonJ

ronjin

-

AuthorPosts